3D Printing & Injection Molding

Full Product Assembly

Your Trusted Supplier of Custom Service

Help you easily achieve your electronic product!

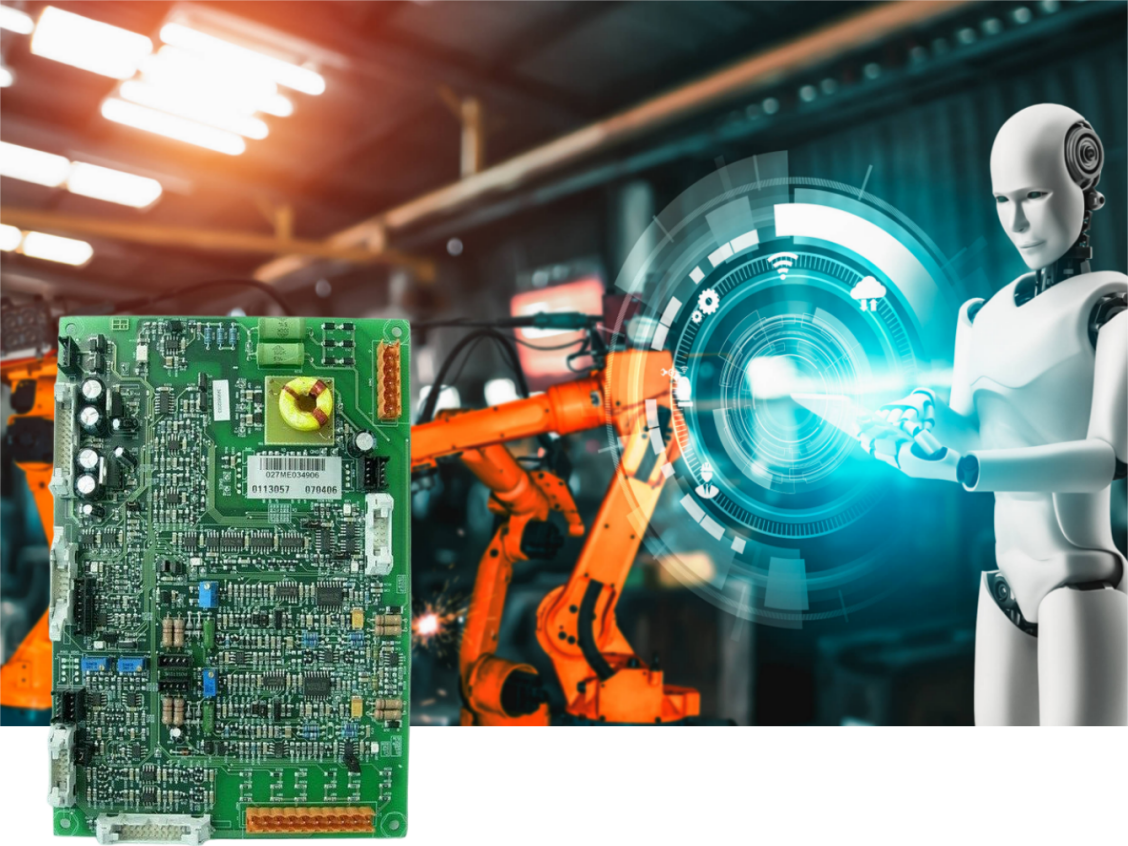

From PCBA production to full product assembly (Box Build), we provide end-to-end solutions to help you easily achieve your electronic products. It’s including PCB manufacturing, component sourcing, SMT/THT, finished product assembly and testing.

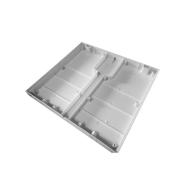

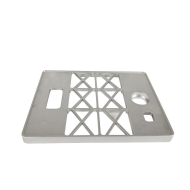

We invested and cooperated with our mold factory —— equipped with advanced precision machining and testing equipment,including high-speed precision CNC machining equipment, wire-cut EDM machines”, mirror spark machine, injection molding machines of 80T/120T/150T/250T, equipped with CAD/CAE/CAM design, manufacture of advanced systems and a complete range of mold processing and inspection equipment, committed to the use of advanced technology, using high-precision machining equipment engaged in precision molds, precision injection molding, precision machining, the maximum for customers with a full range of quality services, the parts are widely using in the common industries of auto, household, medical, office and other.

Whether you need full – scale production or prototype PCB assembly, we support your needs—including enclosure fitting and potting processes. We always adhere to the principle of meeting the needs of our customers provide rapid response and service to a high standard and in a timely manner.

What Custom Service We Offer

Metal 3D Printing, Stereolithography (SLA), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF), PolyJet.

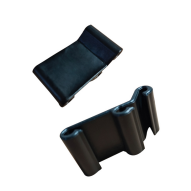

Mold manufacturing, Plastic molding, Silicone molding

Aluminum, Brass, Copper, Steel alloy, ABS.

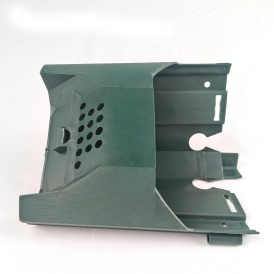

Plastic enclosure, Metal enclosure, Waterproof enclosure.

Gift box packaging, Label printing.

Mold making and Injection molding

With years of experience in manufacturing, we specialize in producing plastic molds with complex structures—such as hot runner molds, overmolds, rotational molds, unscrew molds, and multi-cavity molds. Our plastic molds cater to various industries including automotive, household appliances, medical, office equipment, and electronics.

Our injection molding machines of various tonnages ranging from 80T to 600T. Drawing can be done based on samples. It supports injection molding with molds and raw materials. The processing technicians all have 8 to 10 years of processing experience. The processing process strictly controls dimensions and quality.

Mold making

- Mould machining precision can reach and 0.1 mm

- 2-3 days samples after confirm drawings.

- 15 to 30 days mold making according to the product structure.

- Free maintenance of the mould.

Customization

- Customized based on provided drawings or samples

- Quick and accurate quotations

- Provide technical advice according to customer requirements to reduce product costs

Production Capabilities

- Large / small volume

- Short or long production runs

- Prototype (molded)

- Mold a complete range of engineered and commodity resins

- Insert molding capabilities

- Over molding

- Assembly and secondary service capabilities

Current Molding Specialties

- Threads (internal and external)

- O-ring grooves (tight tolerance)

- Snap fits

- Close tolerance

Production Classification

Mechanical parts series

Electrical appliance housing series

Outdoor series

Customized series of special-shaped parts

Office supplies series

Custom Enclosures Service

Your project, our process: where every trace meets your trust.

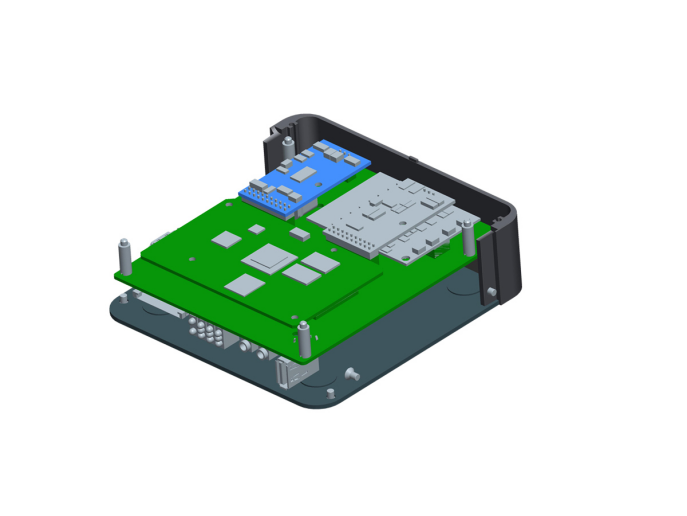

Box build assembly is the process of putting multiple printed circuit boards together into a single housing or enclosure. It brings together various individual components—like PCBs, connectors, and wiring—to form a fully functional electronic system or device.

This physical assembly work requires careful arrangement and connection of these parts. The goal is to build the machine’s internal structure correctly, making sure it operates as it should. Every component is positioned and linked with precision to ensure the entire system functions properly.

Applications of BOX Building

- Protection from Environmental Factors

- Dust and Moisture

- Heat Dissipation

- Robustness

- Signal Integrity

- Material Choices

- Aesthetic and Branding

Advantages of BOX Building

- Protection Against Physical Damage

- Ease of Assembly and Maintenance

- Cost Efficiency

- Reduced Time to Market

- Flexibility and Customization

Full Product Assembly (Box Building Service)

We adhere to the principle of prioritizing quality and service.

Once we get your request, our sales team will reach out quickly to talk through your specific design and needs. From there, we’ll create a tailored, comprehensive box-build assembly solution—one that meets or even goes beyond what you expect. Whether you need something as straightforward as a plastic enclosure or a complex multi-rack assembly, we have the capabilities to deliver strong results.

- Pre-tested subassemblies cut down on costs while keeping quality in check.

- We specialize in solving complex cable assembly challenges. This includes tasks like stripping, tying, tinning, and twisting cable bundles with precision.

- Components like racks, cabinets, and backplanes come fully wired, which deliver complete solutions for your electronic systems.

- We use precision machined parts to craft high-quality subassemblies. These are built to match your specific requirements exactly.

- Our expertise spans enclosures, cable assemblies, and subassemblies alike. We handle both simple projects and complex metal frame setups with equal proficiency.

Partner With JC Teams for Box Building

We adhere to the principle of prioritizing quality and service.

Flexibility and Customization

Leveraging years of design experience and market research, we’ve honed an eye for aesthetically pleasing products. This expertise allows us to offer tailored recommendations for optimizing: visual appeal (refining color schemes, textures, and overall aesthetics), form factor (ensuring ergonomic fit and space efficiency), Functionality (balancing design with practical usability).

Top Service

Customers will receive every update of project progress, ensuring both timeline and quality are meeting. We offer comprehensive after-sales service, including product maintenance, technical support and handling of customer feedback, to ensure that customers can receive timely and effective support and solutions during the use of the products.

Cost Efficiency

With our factory and professional team, we minimize intermediate costs to provide the competitive quotes. Optimizing your project’s budget and timeline with cost-effective strategies and efficient planning.

Years of experience

Since 2008, JC PCBA not only provides PCBA manufacturing but also offers professional custom box building. Leveraging our extensive industry experience and technical accumulation, we can assist customers in considering manufacturing feasibility and cost-effectiveness during the enclosure design phase, ensuring the optimization and innovation of enclosure designs.

Our PCBA Solutions Across Industries

safety protection, electrical appliances, digital home appliances, and more.

Our Testimonials

PCB&Assembly

Everything is good, PCBs work good by now, thank you(Gracias)! To JC Teams.

PCBA programming,conformal coating,testing.

The boards are prefect, I am really happy to receive my boards, the components are really good!

3D Printing&Injection Molding

I am very pleased to work with you(Sulin)! It feels like you are a professional!

PCB Manufacturing

Uploaded my Gerber files, got a quote in hours, and parts arrived sooner than quoted. Nice.”

PCBA Prototyping& Batch production

I am happy to find you(Jason)!No minimum order hassle, and the soldering looks good, cleanly well.

PCBA and components and modules.

We tested all, PCBs works well, thank you! Michael.

PCB Assembly&Testing

Consistently excellent. Quick responses from Joy.

Contact Us

Help you easily achieve your electronic product.

Headquarter Address

SEG Plaza 4406A,No. 1002, Huaqiang North Road,Fuqiang Community, Huaqiang North Street, Futian District. Shenzhen

Factory Address

1st Floor, Building 2, Fenghuang Community, Fuyong Street, Baoan District, Shenzhen, Guangdong, China

Phone

+86-755-85122468

sales@pcbcustom.com

Get Free Quote

Our 1-on-1 sales engineer will reply as soon as possible and quote you within one day!