Automotive PCBs Manufacturing & PCBA Services

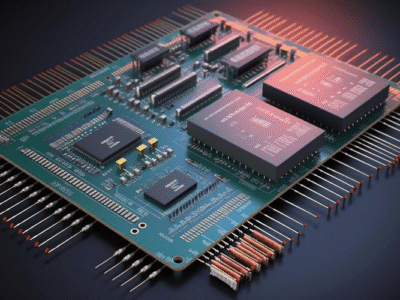

Automobiles have transformed simple mechanical machines into highly complex electronic systems, and this transformation is inseparable from the close integration of PCB technology. With the continuous development of HDI technology and miniaturized SMD components, PCBA boards appear in various corners of automobiles in smaller and more intricate forms. As the central nervous system of automotive electronic systems, PCB facilitates communication and control between various components, meeting the specific customization needs of automobile manufacturers. Today, let’s unveil the mystery of automotive PCBs.

What is an Automotive PCB?

An Automotive PCB is a printed circuit board specifically designed for automotive environments, responsible for signal transmission, power distribution, and data processing in various automotive electronic systems. According to the International Automotive Task Force (IATF), Automotive PCBs must meet the IATF 16949 quality management system standards, with reliability requirements 3-5 times higher than ordinary PCBs. Just as different car models require different chassis, automotive PCBs are custom-designed based on the functional needs of on-board systems, with significant differences in complexity and performance requirements between ordinary fuel vehicles and new energy vehicles.

- Dashboard switches

- ECL/ ECU control units

- Stereo and audio components

- Engine controls

- Power transformers

- AC/ DC power converters

- Temperature sensors

- Transmission sensors

- Digital timers

- Automotive power supplies

- Digital screens and display systems

- On board radar

- Navigation system

- Anti lock breaking systems

- Automated locking systems

- Power relays

- Headlights and interior LED lighting systems

Comparison of Different Types of Automotive PCBs

Classified by application scenarios, automotive PCBs mainly fall into four categories, with differences in the parameter table:

| Type | Typical Size | Layers | Operating Temp | Certification Standard | Core Features | Representative Systems |

| Powertrain | 120x150mm | 8-16 | -40~125℃ | AEC-Q100 Grade 0 | High power, vibration resistance | Motor controller, BMS battery management |

| Body Control | 80x100mm | 4-8 | -40~105℃ | AEC-Q100 Grade 1 | Multi-interface, low power consumption | Lighting control, air conditioning system |

| Infotainment | 100x120mm | 6-10 | -40~85℃ | AEC-Q100 Grade 2 | High-speed signal transmission | Car navigation, audio-visual systems |

| Safety Assistance | 90x110mm | 8-12 | -40~105℃ | AEC-Q100 Grade 1 | High reliability, low latency | ADAS, airbag controller |

Powertrain PCBs can be called the “cardiovascular system,” withstanding the highest temperatures and strongest vibrations; safety assistance PCBs act as “safety guards,” which must never fail under any circumstances.

Key Challenges in Automotive PCB Design

Automotive PCB design is far more stringent than household PCB design, with these key points determining driving safety:

- Environmental tolerance is a lifeline: Temperatures in the automotive engine compartment can reach 125℃, with continuous vibrations (≤2000Hz) during driving. PCBs must use high-temperature substrates (such as FR-4 HT), and solder joints must pass IPC-A-610 automotive-grade certification to ensure stable operation within the -40~125℃

- Electromagnetic compatibility is a required course: On-board electronic systems are dense, causing severe electromagnetic interference. International standard ISO 11452 requires automotive PCBs to pass electromagnetic radiation and anti-interference tests. During design, multi-layer ground planes must be used, and key signal lines must be shielded to avoid “electronic system internal conflicts.”

- Reliability testing cannot be skipped: Every automotive PCB must undergo “severe trials” — temperature cycle testing (-40℃ to 125℃ for 1000 cycles), vibration testing (10-2000Hz sweep vibration), and damp heat testing (85℃/85%RH for 500 hours) — before being installed in vehicles.

- Space utilization must be optimal: Space in automotive electronic compartments is extremely limited. PCBs need to adopt High-Density Interconnect (HDI) technology, with line width and spacing as small as 50μm/50μm, enabling more functions in limited space.

Core Functions of Automotive PCBs

Automotive PCBs are like “versatile housekeepers,” undertaking multiple key tasks:

- Power regulation is the “heart function”: In new energy vehicles, PCBs control motor output power and precisely adjust voltage and current to ensure stable power output. For example, the motor controller PCB of Tesla Model 3 can achieve millisecond-level power regulation.

- Safety monitoring is the “early warning system”: ADAS (Advanced Driver Assistance System) PCBs process camera and radar signals in real-time, completing obstacle recognition and distance calculation within 0.1 seconds to provide decision support for automatic braking.

- Body control is the “coordination center”: It uniformly manages lighting, wipers, air conditioning, and other equipment, enabling collaborative work of various systems through CAN bus. For example, Mercedes-Benz’s body control PCB can process over 200 sensor signals simultaneously.

- Information interaction is the “communication bridge”: It supports car navigation, Bluetooth connectivity, OTA upgrades, and other functions. High-performance infotainment PCBs can achieve data transmission rates of up to 10Gbps, meeting 4K video playback requirements.

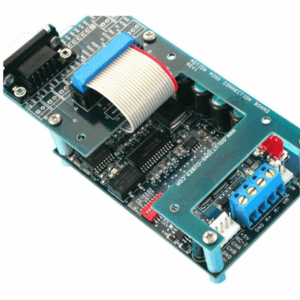

Automotive PCB Application Cases

Examples of some automotive PCB applications include:

ECM:

Modern cars have moved away from traditional engine configurations and now rely on PCB as the core of ECM systems to optimize engine performance, fuel efficiency, and emissions, driving the automotive industry toward a cleaner and more efficient direction.

Safety systems:

Safety systems include features like full airbag deployment, collision detection, and anti-lock braking systems, demanding high reliability and precision. They must respond quickly when drivers face danger to ensure passenger safety.

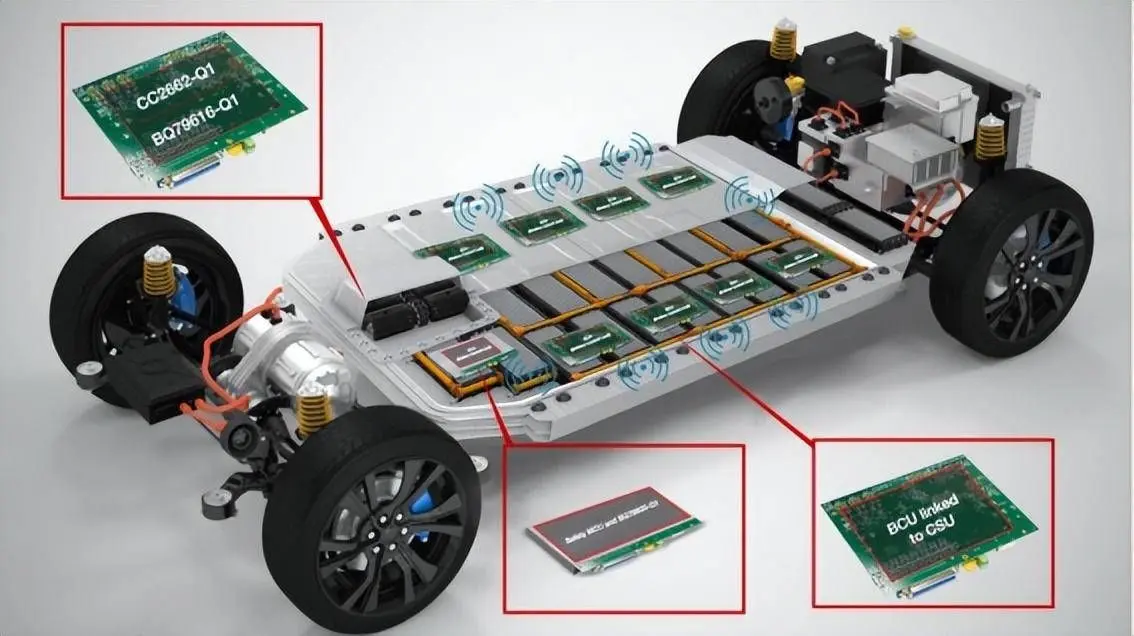

BMS:

With the rise of electric vehicles (EVs), BMS PCBs have become crucial. These PCBs are used to manage and monitor the performance and health of electric vehicle batteries to ensure safety and longevity.

FAQ: Your Concerns Answered

Q1: What is the lifespan of an automotive PCB?

A: The design lifespan matches that of the entire vehicle, typically 8-15 years/200,000 kilometers. High-quality PCBs can withstand over 1000 temperature cycle shocks without failure.

Q2: What’s the difference between new energy vehicle PCBs and traditional automotive PCBs?

A: New energy vehicle PCBs have more layers (8-16 layers), higher temperature resistance (up to 125℃), and need to support high-voltage (400V/800V) designs. BMS battery management PCBs are their unique type.

Q3: How to judge automotive PCB quality?

A: Check certifications (IATF 16949, AEC-Q100), review test reports (temperature cycle, vibration test data), and prioritize products from suppliers with experience in supporting main automakers.

Why Choose JCPCBA for Your Automotive PCBs Assembly Needs?

- Quick Turn Prototype

- SMT/THT Assembly

- Mixed Assembly

- Lead Free Assembly

- Fast Turnaround PCB Assembly

- Prototype & High Volume

- 100% Electrical Testing

- Impedance control

- Blind,Buried and Plugged Vias

- BGA Assembly

- High-Temp,FR4,Flex,HDI,Rogers,etc

Top Quality Guarantee:

100% electrical testing, AOI, IQC, OQC, and X-ray inspection for defect-free PCBs, which meet RoHS, ISO9001 standards and the standards of IPC Class II. We always react immediately if any issue and provide a quick solution. JC PCBA guarantee the quality, free maintenance and after-sales service for 2 years.

Privacy Protection:

Customer design files are confidential information. We strictly protect all information provided by our customers, ensuring your proprietary information is protected from disclosure, all data is secured and encrypted.

1-on-1 Service :

We taking full responsibility for every customer while offering dedicated 1-on-1 technical team support throughout the pre-sales, in-sales, and after-sales stages. During production, our 1-on- 1 sales will keep you updated of all the progress immediately enable you to master every detail of the production process.

Fast, Efficient, No MOQ:

Generally, our PCB sample take 1-3 days, mass production takes 5-7 days, PCB assembly samples are completed in 10-15 days, and PCB assembly mass production is finished within 15-20 days. Besides, we have one fast sample line for urgent orders.

HOW TO GET A QUOTE: If you want to get a quick quotation for the PCB, please reach us at sales@pcbcustom.com.

Conclusion

PCBs are now essential in modern cars because of the revolution in electronics. Understanding signal integrity, reliable power distribution, temperature control, and mechanical dependability is vital to designing automotive PCBs. The PCB board of an automobile is a critical electrical component that needs to be highly stable, safe, and reliable. Automotive PCB boards may maximize the driving experience and performance of the car, in addition to enhancing the functionality and efficiency of automotive circuits. Contact us at sales@pcbcustom.com today!

Related Posts

Telecom PCBs Manufacturing: Printed Circuit Board in Telecommunication

Smart Home PCB Manufacturing & PCBA Services

Medical PCB Assembly and Manufacturing

LED PCBs: Building the Core of Efficient Lighting

Industrial PCBs Manufacturing & PCBA Services

Consumer Electronics PCBA Manufacturer – JCPCB

Automotive PCBs Manufacturing & PCBA Services

Contact Us

Help you easily achieve your electronic product.

Headquarter Address

SEG Plaza 4406A,No. 1002, Huaqiang North Road,Fuqiang Community, Huaqiang North Street, Futian District. Shenzhen

Factory Address

1st Floor, Building 2, Fenghuang Community, Fuyong Street, Baoan District, Shenzhen, Guangdong, China

Phone

+86-755-85122468

sales@pcbcustom.com

Get Free Quote

Our 1-on-1 sales engineer will reply as soon as possible and quote you within one day!