FAQ

Most Popular Questions

1.Submit Requirement: Please send your relevant design documents (such as Gerber/Bom) and requirements. We strictly protect all information provided by our customers. Send us:sales@pcbcustom.com

2.Received Quotation: You will receive feedback from a dedicated salesperson providing one-on-one service throughout your entire process within 6 hours and a customized quotation within 24 hours.

3.Sign the Contract:After fully understanding the customer's requirements and confirming the price, lead time, payment method, transportation and qualification certification, sign the PI agreement and make prepayment.

4.Production & Delivery:After receiving prepayment, production will be arranged immediately. During the production process, your full-time salesperson will proactively report the production progress to you. Before shipment, detailed photos, test videos and packaging of the products will be taken for your confirmation.

5.After-sales & Repurchase: We will always react immediately if there is any issue and provide a quick solution. JC PCBA guarantee the quality and after-sales service for 2 years. If everything well, we will welcome further cooperation.

Yes, we offer expedited prototyping for urgent needs. Our streamlined workflow, dedicated engineers, and advanced equipment enable rapid turnaround—24–72 hours for standard specs, varying by complexity (e.g., layers, materials).

Share your design files and requirements, and we’ll promptly provide a detailed quote and exact delivery schedule. Send us:sales@pcbcustom.com

Your files are maintained with complete safety and security. We safeguard our customers' intellectual property throughout the entire process, and all customer documents are never disclosed to third parties. A non-disclosure agreement (NDA) can also be signed to formalize this commitment.

We have no minimum order quantity (MOQ) requirement. With flexible production capabilities, we efficiently handle both small and large volume orders. Additionally, we operate one dedicated expedited prototyping lines to support rapid turnaround needs.

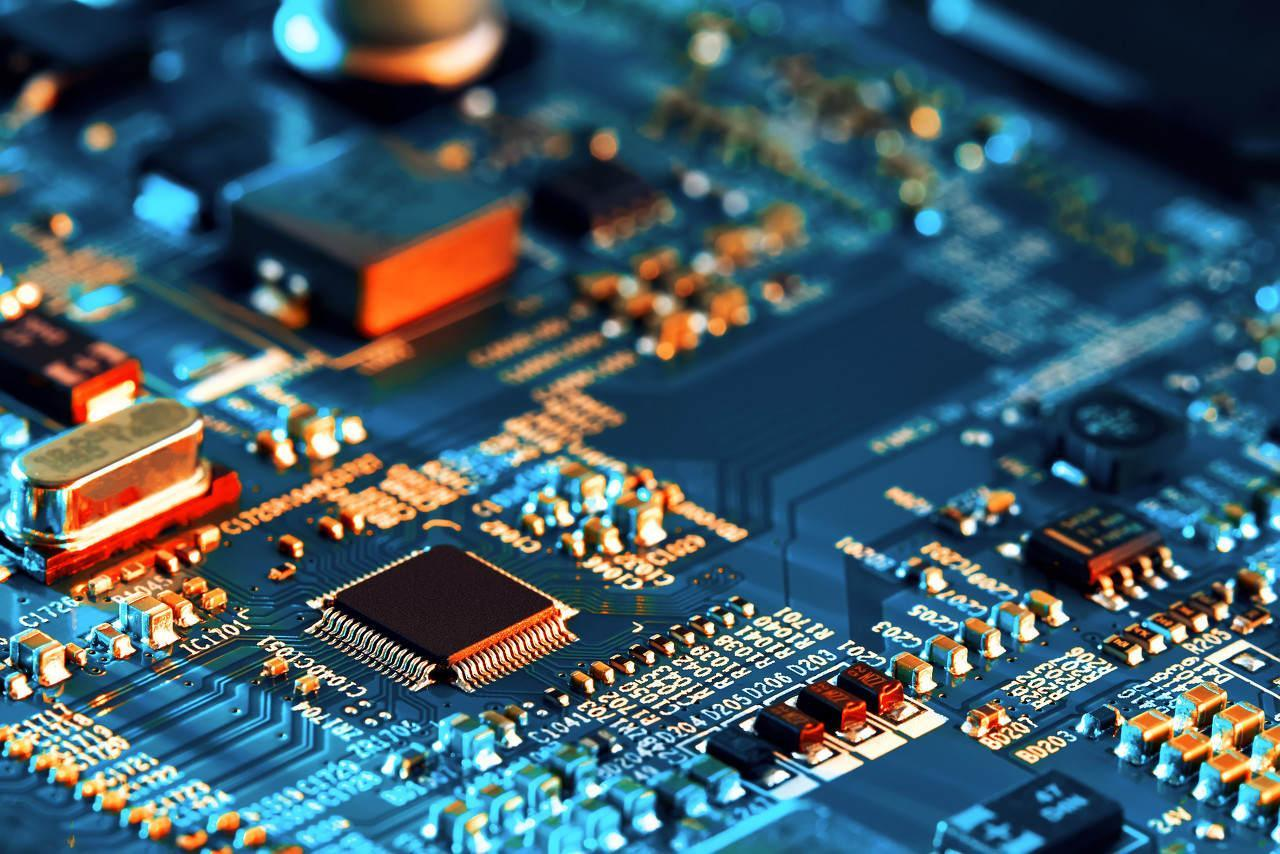

We provide one-stop OEM services, including PCBA fabrication, PCB assembly, and component sourcing. Furthermore, we offer additional support such as programming, testing, cable supply, and enclosure assembly. More service pls ask our technical:sales@pcbcustom.com

To ensure PCB quality, we typically conduct rigorous testing using methods such as flying probe testing, E-test, AOI inspection, power-on testing, X-ray inspection for BGA components, first article inspection (FAI), and manual inspection and LED lighting tests on the PCBA.

Besides, Reliability testing is divided into aging testing, vibration testing, collision testing, drop testing, packaging pressure testing, etc. We have corresponding equipment to conduct tests.

We taking full responsibility for every customer while offering dedicated 1-on-1 technical team support throughout the pre-sales, in-sales, and after-sales stages. The meaning of one-on-one service is that each customer is served by a professional team of ours throughout the entire process: quotation, production, delivery, and after-sales service. You only need to communicate your requirement with us and we will handle everything for you. Send your inquiry: sales@pcbcustom.com

If your project require programming and functional testing before delivery, our project manager will follow your instruction and the testing workers will be trained to familiar with all steps. And we are proficient in the design of customized functional testers and the production of fixtures.

All programming and testing steps process will be confirmed with you via videos, JC team will make sure all of your instructions will be listen and followed and our goal is make sure your PCBA 100% pass the test. All defective issues and reasons will be recorded and share with you for further improving action.

PCB FAQ

CAM350/Altium Designer/Genesis2000//PADS/GC-power.

Our company's engineering team offers free DFM analysis. All data will be reviewed and confirmed after production. If there are any issues, an EQ confirmation will be issued.

The electrical testing of PCBS mainly involves checking whether there are any open or short circuit issues on the PCB board and analyzing whether it matches the customer's design

CTI stands for Tracking Index, which is the voltage at which marks are left on the surface of a board when it leaks and burns. For conventional FR4 boards, the CTI value is PLC3, that is, 175<CTI<245.

For finished plate thickness less than 1mm, it can be controlled at +/-0.1mm. For finished plate thickness greater than 1mm, the strictest control can be +/-0.13mm. Normally, it is controlled at +/-10%. (Because the plates and materials such as pp have certain tolerances, and the chip tolerance close to +/-0.075mm).

Electronic Component FAQs

Our company's procurement channels include spot platforms such as Digikey, Mouser, and Ickey, as well as our trusted supplier channels. Our company will make purchases based on the qualifications and advantages of component suppliers. Additionally, we have IPQC to conduct incoming parts inspections, and we will also check the supply channels of each batch of incoming parts to ensure that the goods are original. If alternative materials are needed, our company will confirm with the customer.

Sure. If the customer has the need, our company will keep a record of the incoming parts and send the RoHS certification and batch number to the customer.

First, our purchasing team will check the best prices in stock in the market and offer to customers, as well as suggestions for booking futures. Meanwhile, our engineering team will provide some alternative solutions for customers' reference, and we will also contact the original factory to offer some alternative solutions.

We will classify and store components according to the types. Important components such as IC will be placed in dedicated drying ovens, while other regular materials will be properly labeled and stored in the warehouse.