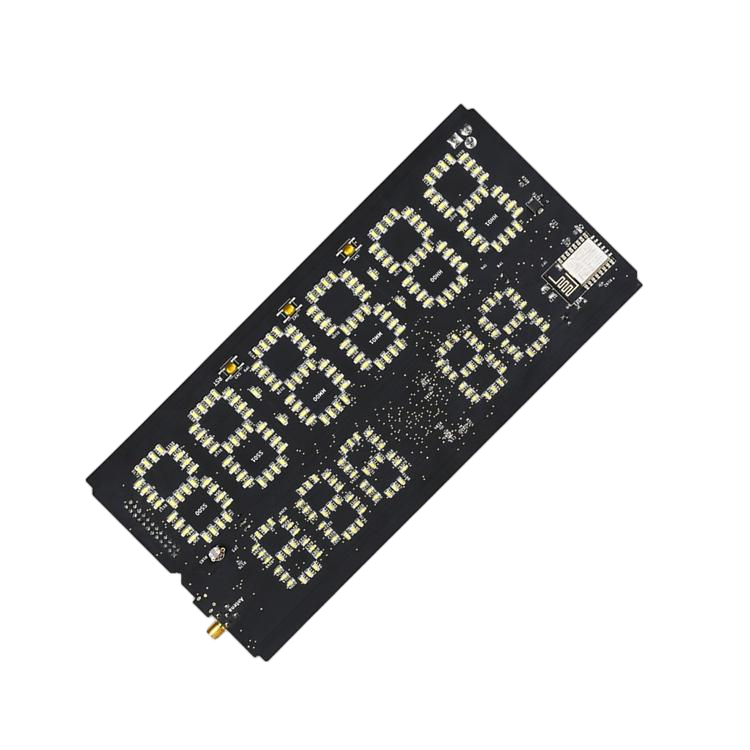

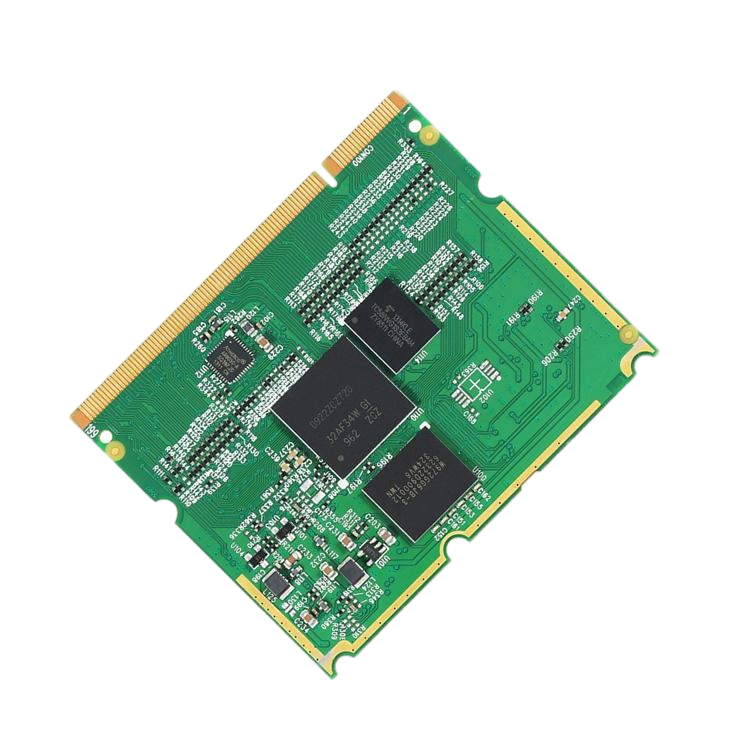

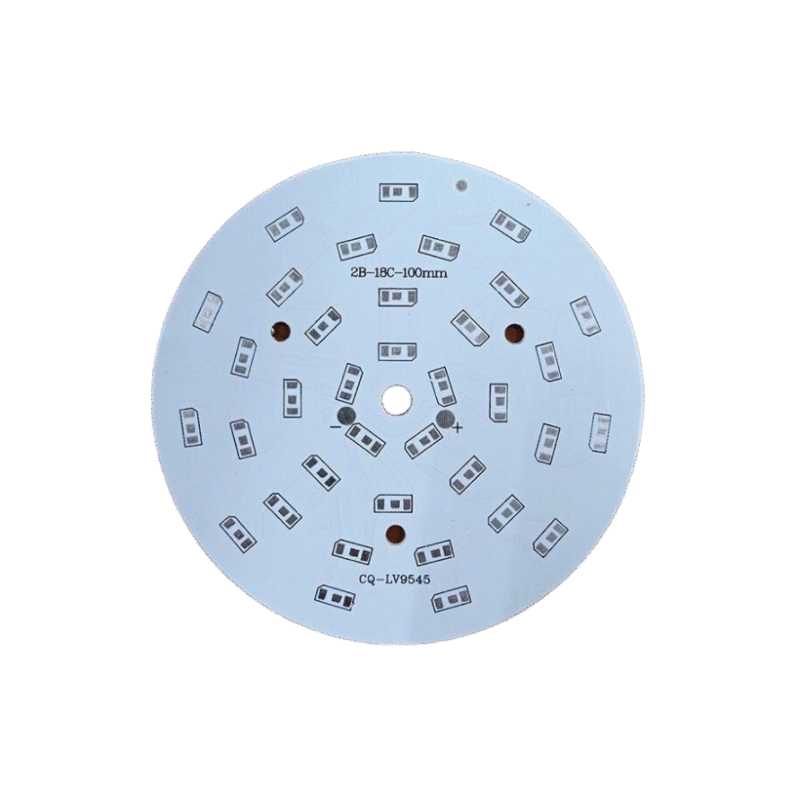

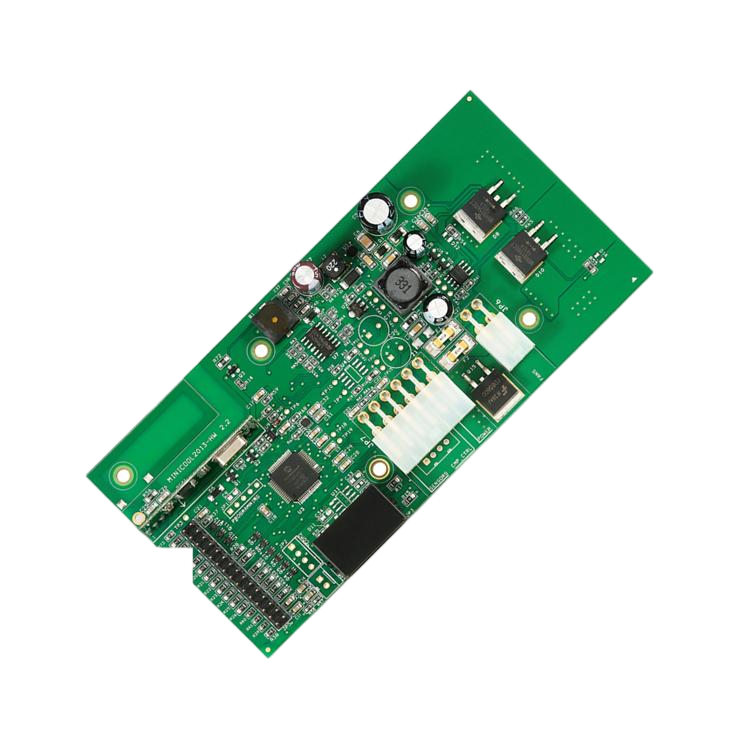

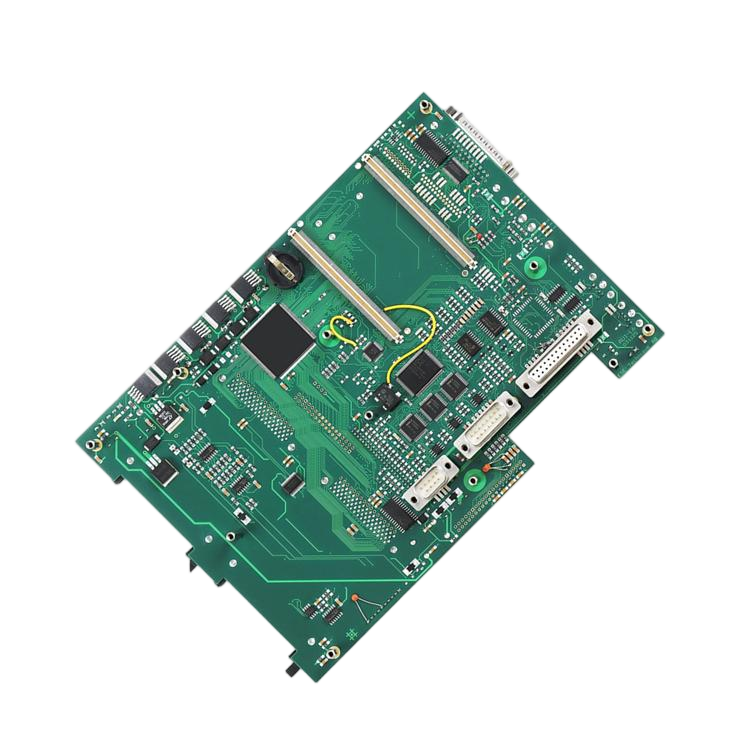

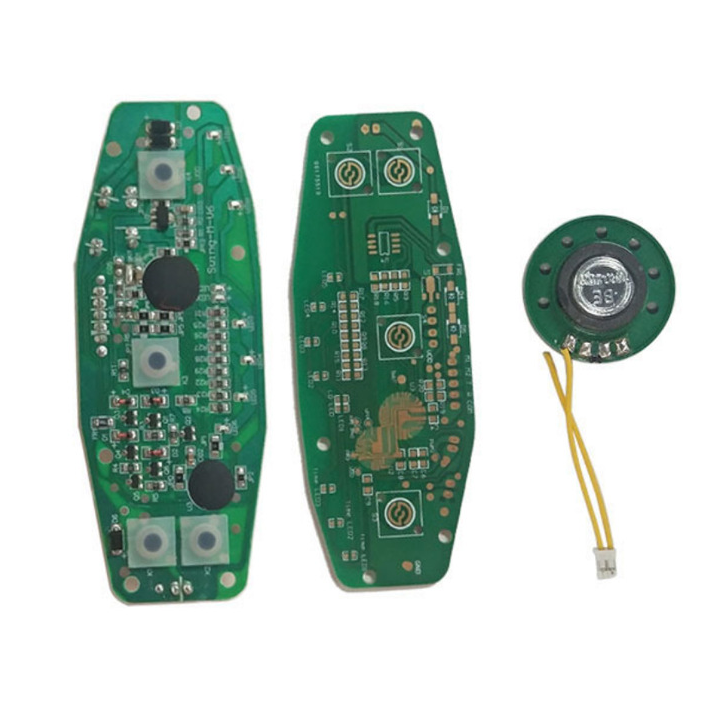

PCB Assembly

Your One-Stop OEM PCBA Manufacturing Partner

JCPCB is a trustworthy and professional PCB assembly company in China, offering one-stop PCB manufacturing and PCB assembly electronic manufacturing services (EMS).

We provide a full system assembly service for products, such as SMT,PTH,COB,AOI,X-RAY,0201,QFP,BGA,UBGA,CBGA, Electronic, Mechanical Assembly. Our manufacturing facilities are ISO9001 and UL certified, RoHS, IPC-A-600 and IPC-A-610 compliant.

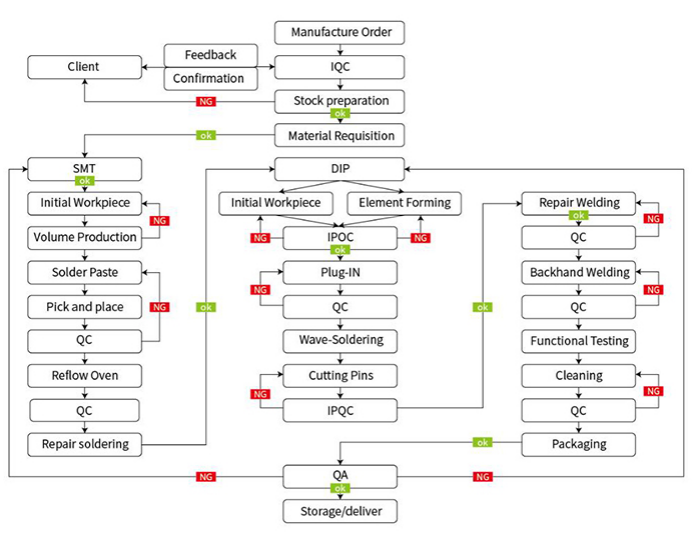

Our PCB Assembly Process

From prototype to production, we solder trust into every board.

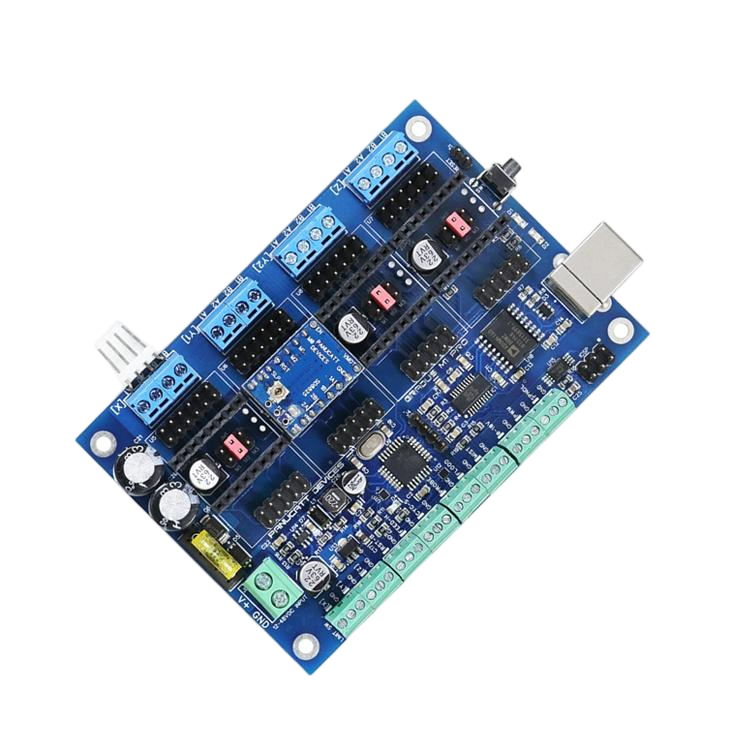

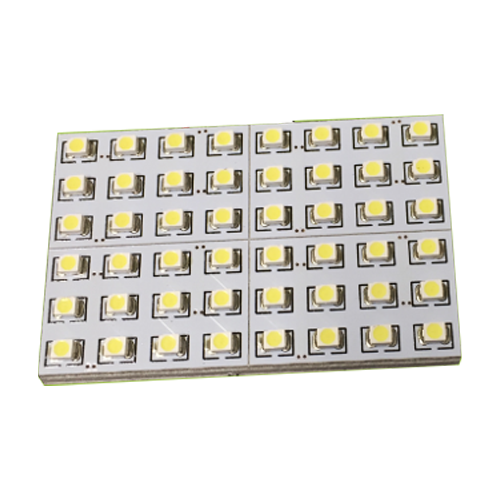

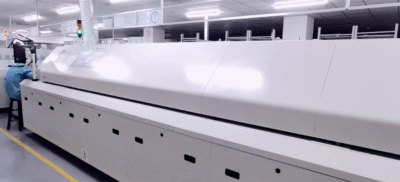

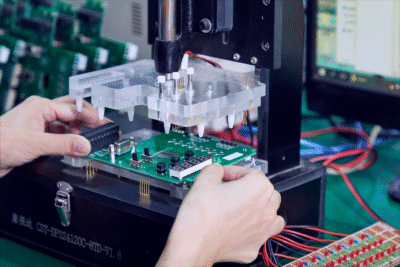

一、SMT(Surface Mount Technology)

Our highly flexible surface mount technology (SMT) production line and rapid conversion or adaptation capabilities are designed to produce high-quality, 0201 SMT component assembly, BGA assembly, POP assembly process, fine-pitch soldering, high-mix, 0201, BGA, CCGA, CSP, QFP. Our manufacturing model is tailored to meet the unique needs of our customers.

Baking (PCB, components); Auxiliary materials (solder paste thawing, stirring); Material counting (line changeover);

- Baking (PCB, components) to remove moisture and prevent pop-up defects during soldering;

- Auxiliary materials management - solder paste thawing at room temperature, vacuum stirring to ensure uniform viscosity; Storage environment for solder paste: Store at a low temperature of 2-8℃. Stirring time before solder paste use: Machine stirring for 3 to 5 minutes or manual clockwise stirring for 15 minutes. Operate strictly in accordance with the solder paste usage specifications.

- Material counting and verification including BOM matching during line changeover to avoid wrong parts;

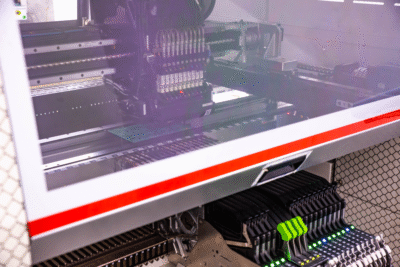

Automated workflow: Board loader→Printer→SPI

- Automatedboard loader (precisely feeding PCBs)

- Printer (stencil alignment for accurate paste deposition)

- SPI (Solder Paste Inspection,analysis to detect defects like insufficient paste, bridging, misalignment in real time);

- Solder paste printing (SPI solder paste inspection: thickness, area, shape...) ;

High-speed machine (for chip components like resistors and capacitors with high placement speed up to 80,000 CPH);

High-speed machine (for chip components like resistors and capacitors with high placement speed up to 80,000 CPH);- Universal/multi-functional machine (for odd-form components, BGA, QFP, and other chips with high precision placement accuracy of ±0.03mm);

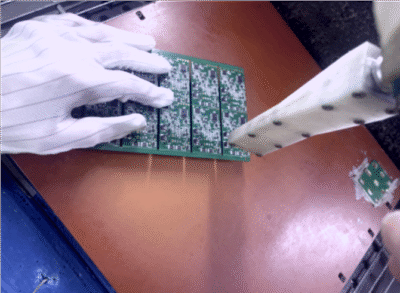

- Machine surface mount technology (material change record form and samples, SMT first piece record form, IPQC line inspection record form, equipment inspection and maintenance record form, RF inspection record form...)

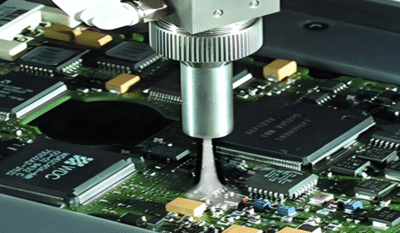

Achieve alloy soldering and curing of solder paste and red glue by selecting appropriate process curve temperatures: Achieve reliable alloy soldering of solder paste and curing of red glue by selecting temperature profiles (preheating, soaking, reflow, cooling zones) tailored to component types and PCB thickness, ensuring no cold solder joints or thermal damage; Furnace temperature curve, temperature usage instruction manual, operation procedures and QC&AOI inspection statistical records;

- Conduct visual inspection and internal X-ray inspection for different types of components. Perform statistical analysis, eliminate defects, and achieve positive feedback.

- 100% of all products pass AOI inspection.100% X-ray inspection on BGA parts.

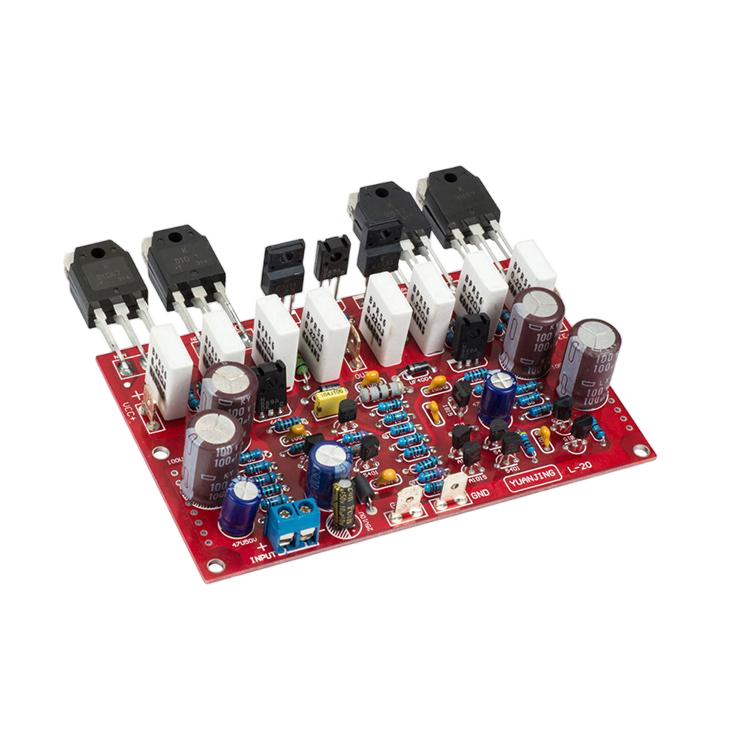

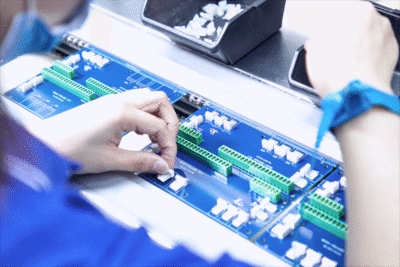

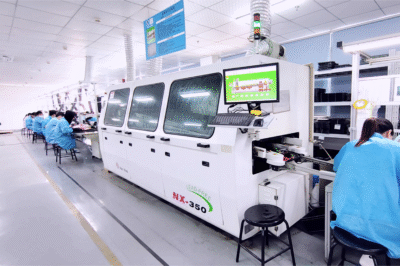

二、DIP/THT (Through Hole Technology)

- Automatic DIP: Use an automatic insertion machine to automatically insert electronic components into the corresponding positions on the PCB board according to the preset program and coordinates. The automatic insertion machine features high speed, high precision and high efficiency, and is suitable for large-scale production.

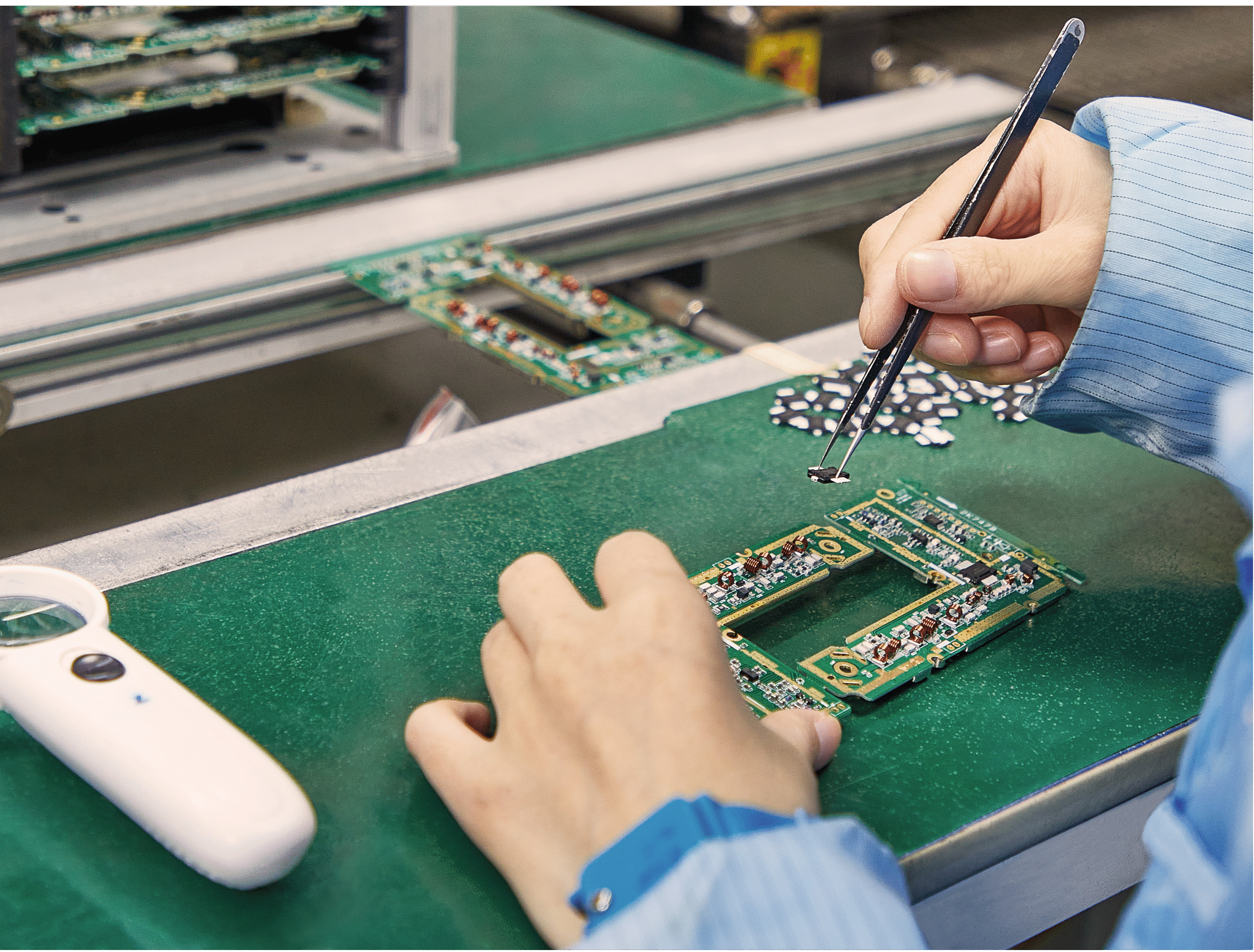

- Manual DIP: For some special or irregular-shaped components, JCPCBAhave operators with proficient skills and rich experience to ensure the accuracy and consistency of the insertion.

- PCB preparation: Cleaning and drying to ensure that the surface is clean and dry, and check whether the holes on the PCB meet the design requirements.

- Component shaping and lead cutting: Components need to be tested to ensure that their quality and performance meet the requirements.The pins of the components also need to be pre-treated, such as bending and trimming, to facilitate insertion and soldering. (adjusting lead spacing to match PCB holes, trimming lead length to 2-3mm for optimal soldering);

- Pre-assembly of small components (e.g., terminal blocks, connectors) to simplify subsequent DIPsteps.

Insert DIP components into corresponding holes in strict accordance with process specifications and customer requirements including height restrictions, polarity orientation, gasket installation, and suspension for heat dissipation or insulation;Insert the prepared DIP components into the corresponding holes on the PCB as per the design requirements. This step requires precise operation and meticulous observation to ensure that the pins of the components are aligned with the holes on the PCB, avoiding pin bending or damage.

After the plug-in is completed, the components need to be firmly connected to the PCB through the soldering process. Common welding methods include wave soldering, manual soldering, etc. During the welding process, it is necessary to control the welding temperature and time to avoid damage to the components and PCB. Flux application via heating and atomization to remove oxides;

- Single-wave for through-hole filling & dual-wave for solder joint smoothing,processes for through-hole tinning;

- Manual solder addition at special positions (e.g., large pads, heat sinks) to increase solder fillet thickness and enhance mechanical strength;

- Cut off excess lead length after soldering: Post-soldering lead trimming to standard length (1.5-2mm) to prevent short circuits;

- Clean residual rosin (manual, ultrasonic, dry ice):Removal of residual rosinusing manual wiping, ultrasonic cleaning with solvent, or dry ice blasting for residue-free, corrosion-resistant surfaces.

Comprehensive inspection of solder joints for continuity, voids, and fillet formation and components for correct placement, polarity, and damage via visual checks and automated testing tools;

三、Programming&Test&Coating

For projects needing programming, offline pre-programming is performed for some components to save production time, while in-line programming is applied for others to ensure data synchronization;

Our range of IC programming Service include:MCU/MPUEPROM,EEPROM,FLASH,NandFlash, PLD/CPLD, SDCard, TFCard, CFCard, eMMC, eMMC, MoviNand, DIP/SDIP/SOP/MSOP/QSOP/SSOP/TSOP/TSSOP/PLCC/QFP/QFN/MLP/MLF/BGA/CSP/SOT/DFN.

Our range of test capabilities include: Automated Test Equipment、Flying probe、 AOI (Automated Optical Inspection)、X-Ray、Burn-in(temperature soak)、 Mechanical fixturing、ICT(in-circuit test)、Solder Paste Inspection、MDA (manufacturing defect analysis)、In-circuit functional test、Automated test、software development、Manual、Electrical safety test、RF test(radio-frequency)、Cable/Harness Test.

- Key Processes: incoming Material inspection - Printing - SPl inspection - SMT Placement - First Article Inspection Reflow Soldering - AOl Testing - insertion - Wave Soldering - Testing - Frequency Adjustment - Aging - Quality Inspection;

- inspection Processes: Incoming Material inspection - SPl lnspection - First Article Inspection - AOl Testing Microscope Inspection - Functional Test Inspection -Quality Appearance inspection;

- Laboratory - Aging Test - Vibration Test Equipment - Drop Test Equipment - Salt Spray Test Equipment - Constant Temperature and Humidity Chamber - Dielectric/Earth Bond Test Equipment

- Key Equipment: Printer - SPl - SMT Machine - Reflow Soldering - AOl Equipment - Wave Soldering

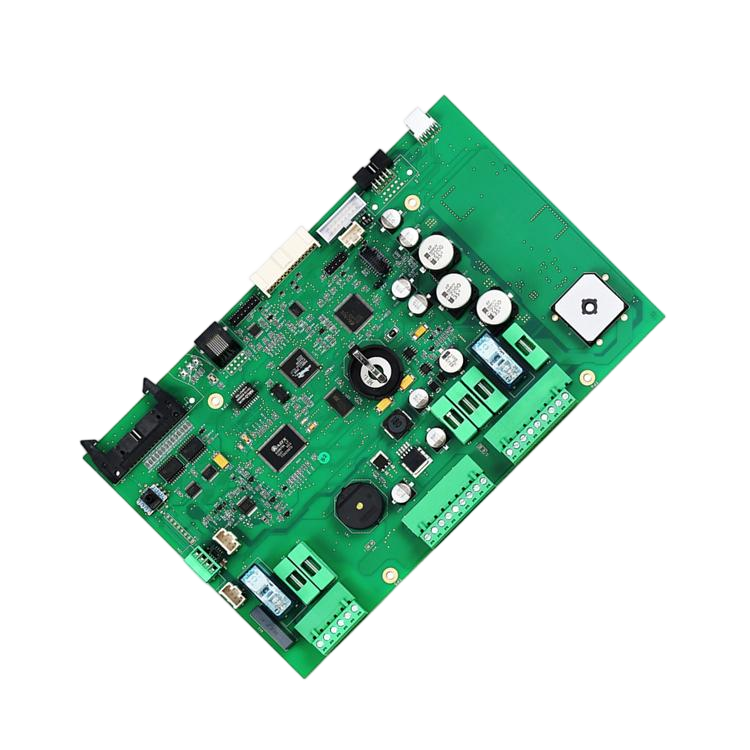

- Standard conformal coating (acrylic, silicone) for basic moisture and dust protection;

- UVconformal coating : fast curing and high production efficiency;

- Nano-coating via PECVD

- CVD :ultra-thin, uniform layers with excellent adhesion and corrosion resistance;

We offer comprehensive coating and packaging services to protect sensitive electronic products from environmental hazards. When your electronic solutions need to operate in harsh environments, whether in the aerospace, defense, medical, industrial or railway transportation industries.

JCPCBA provide send-to-end solutions through full systems assembly、Mechanical Assembly、box build services、Cable Harness Manufacturing& Interconnect Assembly.

Assemble finished products according to customer requirements, PCBA with enclosures, cables, and peripherals according to customer drawings.

- Final inspection and FQCbefore packaging;

- Packaging: Anti-static bags, ESD trays, or custom packaging to prevent damage during transportation;

- Shipping: Fedex, DHL,UPS or others that meet customers need. We will immediately arrange shipment, and provide packing lists, invoices and waybills. And we will keep an eyes on the deliveryuntil the goods are safely delivered to your destination.

WHY PARTNER WITH JCPCB?

1.Price Advantage

We have 15+ years’ cooperated directly with world-renowned original IC manufacturers. On the premise of meeting your functional requirements, our experienced engineer teams will suggest cost-effective alternative solution to optimize the cost of your project.

2.Fast Delivery Time

An efficient internal management system and professional team have streamlined numerous cumbersome workflows, ensuring that every customer’s order is delivered ahead of expectations. PCB assembly samples are completed in 10-15 days, and PCB assembly mass production is finished within 15-20 days. Besides, we offer fast turnaround service for prototype and mass production.

3.Real-time production update

Once production started, we will keep you update: when PCB done, when components collection done, Assembly schedule and estimated delivery date. Our 1V1 sales will keep you updated of all the progress immediately enable you to master every detail of the production process. We taking full responsibility for every customer while offering dedicated 1-on-1 technical team support throughout the pre-sales, in-sales, and after-sales stages.

4.Two years’ Warranty

We will always react immediately if there is any issue and provide a quick solution. JC PCBA guarantee the quality, free maintenance and after-sales service for 2 years. 100% electrical testing, AOI, IQC, OQC, and X-ray inspection for defect-free PCBs, which meet RoHS, ISO9001 standards and the standards of IPC Class II.

Contact us to explore how our PCBA expertise can elevate your industry-specific products’ performance and reliability.

Our Testimonials

PCB&Assembly

Everything is good, PCBs work good by now, thank you(Gracias)! To JC Teams.

PCBA programming,conformal coating,testing.

The boards are prefect, I am really happy to receive my boards, the components are really good!

3D Printing&Injection Molding

I am very pleased to work with you(Sulin)! It feels like you are a professional!

PCB Manufacturing

Uploaded my Gerber files, got a quote in hours, and parts arrived sooner than quoted. Nice.”

PCBA Prototyping& Batch production

I am happy to find you(Jason)!No minimum order hassle, and the soldering looks good, cleanly well.

PCBA and components and modules.

We tested all, PCBs works well, thank you! Michael.

PCB Assembly&Testing

Consistently excellent. Quick responses from Joy.

Frequently Asked Questions

1.Submit Requirement: Please send your relevant design documents (such as Gerber/Bom) and requirements. We strictly protect all information provided by our customers. Send us:sales@pcbcustom.com

2.Received Quotation: You will receive feedback from a dedicated salesperson providing one-on-one service throughout your entire process within 6 hours and a customized quotation within 24 hours.

3.Sign the Contract:After fully understanding the customer's requirements and confirming the price, lead time, payment method, transportation and qualification certification, sign the PI agreement and make prepayment.

4.Production & Delivery:After receiving prepayment, production will be arranged immediately. During the production process, your full-time salesperson will proactively report the production progress to you. Before shipment, detailed photos, test videos and packaging of the products will be taken for your confirmation.

5.After-sales & Repurchase: We will always react immediately if there is any issue and provide a quick solution. JC PCBA guarantee the quality and after-sales service for 2 years. If everything well, we will welcome further cooperation.

Yes, we offer expedited prototyping for urgent needs. Our streamlined workflow, dedicated engineers, and advanced equipment enable rapid turnaround—24–72 hours for standard specs, varying by complexity (e.g., layers, materials).

Share your design files and requirements, and we’ll promptly provide a detailed quote and exact delivery schedule. Send us:sales@pcbcustom.com

Your files are maintained with complete safety and security. We safeguard our customers' intellectual property throughout the entire process, and all customer documents are never disclosed to third parties. A non-disclosure agreement (NDA) can also be signed to formalize this commitment.

We have no minimum order quantity (MOQ) requirement. With flexible production capabilities, we efficiently handle both small and large volume orders. Additionally, we operate one dedicated expedited prototyping lines to support rapid turnaround needs.

We provide one-stop OEM services, including PCBA fabrication, PCB assembly, and component sourcing. Furthermore, we offer additional support such as programming, testing, cable supply, and enclosure assembly. More service pls ask our technical:sales@pcbcustom.com

To ensure PCB quality, we typically conduct rigorous testing using methods such as flying probe testing, E-test, AOI inspection, power-on testing, X-ray inspection for BGA components, first article inspection (FAI), and manual inspection and LED lighting tests on the PCBA.

Besides, Reliability testing is divided into aging testing, vibration testing, collision testing, drop testing, packaging pressure testing, etc. We have corresponding equipment to conduct tests.

We taking full responsibility for every customer while offering dedicated 1-on-1 technical team support throughout the pre-sales, in-sales, and after-sales stages. The meaning of one-on-one service is that each customer is served by a professional team of ours throughout the entire process: quotation, production, delivery, and after-sales service. You only need to communicate your requirement with us and we will handle everything for you. Send your inquiry: sales@pcbcustom.com

If your project require programming and functional testing before delivery, our project manager will follow your instruction and the testing workers will be trained to familiar with all steps. And we are proficient in the design of customized functional testers and the production of fixtures.

All programming and testing steps process will be confirmed with you via videos, JC team will make sure all of your instructions will be listen and followed and our goal is make sure your PCBA 100% pass the test. All defective issues and reasons will be recorded and share with you for further improving action.

Contact Us

Help you easily achieve your electronic product.

Headquarter Address

SEG Plaza 4406A,No. 1002, Huaqiang North Road,Fuqiang Community, Huaqiang North Street, Futian District. Shenzhen

Factory Address

1st Floor, Building 2, Fenghuang Community, Fuyong Street, Baoan District, Shenzhen, Guangdong, China

Phone

+86-755-85122468

sales@pcbcustom.com

Get Free Quote

Our 1-on-1 sales engineer will reply as soon as possible and quote you within one day!