LED PCBs: Building the Core of Efficient Lighting

LED lighting is ubiquitous in our daily lives. More and more lighting is being replaced by LED (Light-emitting diode) solutions because, compared with traditional lighting bulbs, LED lighting has lower power consumption, longer service life and higher energy efficiency.

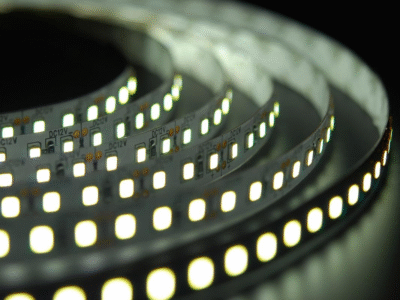

Understanding LED PCBs

LED PCBs are specialized circuit boards designed for LED devices, with core functions of enabling electrical connections and efficient thermal management for LEDs. Approximately 70% of LED energy converts to heat during operation. Poor heat dissipation not only reduces luminous efficiency but drastically shortens lifespan (LED lifespan may decrease by 50% for every 10℃ temperature rise). Therefore, LED PCBs use special materials (like metal cores, high thermal conductivity dielectric layers) and structural designs (thermal vias, copper profiles) to quickly dissipate heat—this is their key difference from standard PCBs.

Advantages of led pcb:

- Efficient Thermal Management

- Energy Efficiency

- Customizable

- Environmental Benefits

- Compact Design

- Enhanced Durability

- Dust and moisture resistant

- Long Lifespan

Applications of LED PCBs: Lighting Scenarios Everywhere

From daily lighting to industrial equipment, LED PCBs appear across multiple fields:

- Automotive Lighting: Headlights, taillights, interior ambient lights require vibration-resistant, high-temperature aluminum or copper-based LED PCBs;

- Outdoor Lighting: Streetlights, tunnel lights, landscape lights rely on high-heat-dissipation metal-core PCBs for harsh environments;

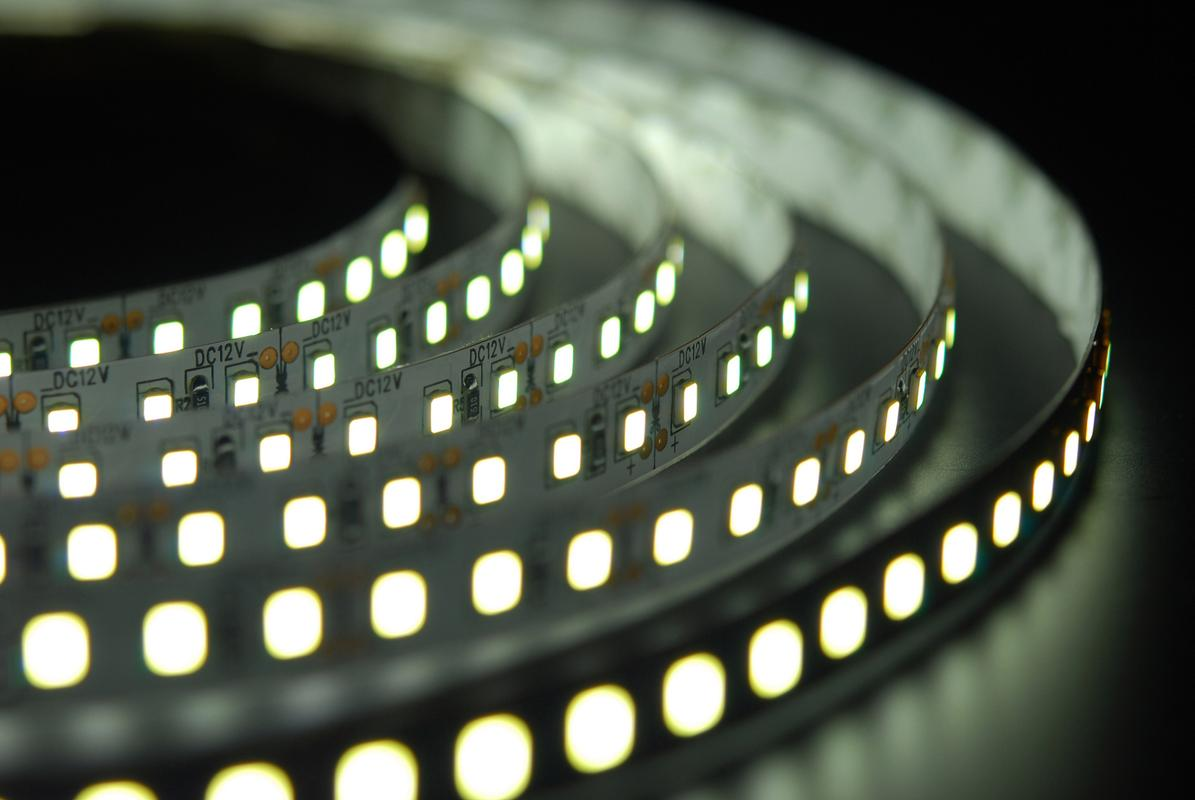

- Consumer Electronics: TV backlights, smart lamps use flexible LED PCBs for thin profiles and design flexibility;

- Medical Equipment: Surgical lights, detector illumination need ceramic PCBs for high stability and insulation;

- Specialized Lighting: Marine lights, portable warning lights achieve directional lighting and vibration resistance through 3D structural designs.

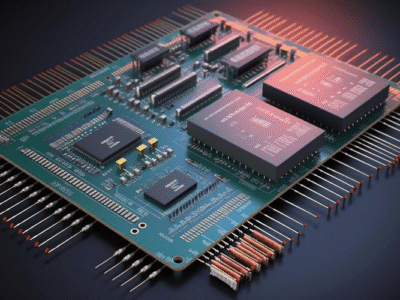

Comparison of LED PCB Types: Choosing the Right Material Matters

| Type | Thermal Conductivity (W/m·K) | Advantages | Applications |

| Aluminum PCB | 1-8 | Cost-effective, lightweight, easy to process | Medium-power LEDs (household lights, car taillights) |

| Copper PCB | 1-398 | High thermal conductivity, strong current capacity | High-power LEDs (industrial lights, streetlights) |

| FR4 PCB | 0.3 | Excellent insulation, extremely low cost | Low-power LEDs (indicators, night lights) |

| Ceramic PCB | 20-200 | High-temperature resistance, strong chemical stability | Extreme environments (medical, aerospace) |

| Flexible PCB | 0.1-0.5 | Bendable, thin and lightweight | Irregular lighting (light strips, curved screens) |

Comparison of CEM-3 and FR-4 Materials

- Compared to CEM-3 and FR-4 materials, aluminum and copper alloys perform better in thermal conductivity. However, since copper alloy is much more expensive than aluminum, and considering thermal performance, rigidity, and cost, aluminum is definitely the most economical choice.

- LED aluminum substrates use aluminum as the heat-conducting base material, offering excellent heat dissipation. They are mainly used in producing high-power LED lighting. FR-4 glass fiber circuit boards use glass fiber as the base material and feature insulation, corrosion resistance, pressure resistance, and multi-layer printing. They are widely used in traditional electronics and LED displays. When evaluating aluminum substrates, pay attention to the aluminum type, hardness, surface treatment, and thickness. Due to their high technical maturity, FR-4 glass fiber boards are commonly used in single-color LED display modules.

- The main reason for using aluminum substrates is their good heat dissipation. Since high-power LEDs generate a lot of heat, most aluminum substrates are used in LED lighting production. FR-4 glass fiber circuit boards are traditional electronic circuit boards. Thanks to their strong insulation, corrosion resistance, pressure resistance, and multi-layer printing, they are widely used.

- For LED aluminum substrates, product quality mainly depends on the aluminum type, hardness, surface, and thickness. The right size should also be chosen based on the product’s heat output. FR-4 glass fiber boards are a mature product and are often used in LED displays.

Production Steps:

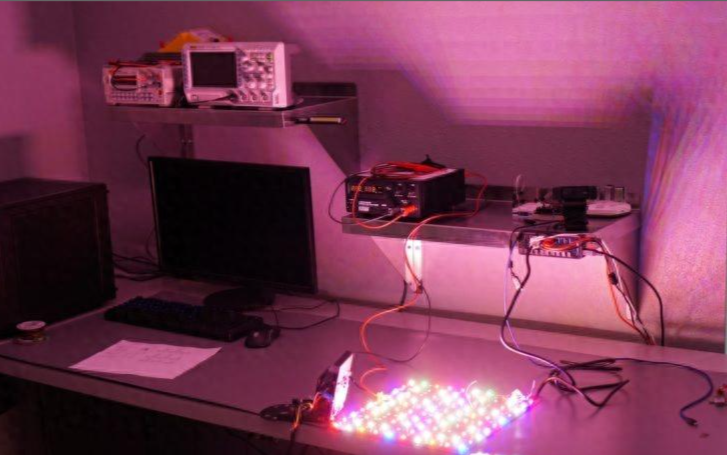

- Design Phase: Complete schematics and layouts using Altium, AutoCAD, focusing on thermal via planning and copper thickness (35-400μm for high power);

- Material Selection: Choose substrates based on power (copper for high power, aluminum for cost-sensitive medium power) and determine dielectric layer thickness;

- Manufacturing: Form circuits through photolithography and etching, integrate thermal management structures (like HSMtec® localized copper profiles);

- Assembly & Testing: Use SMT (Surface Mount Technology) or COB (Chip-on-Board) for LED assembly, testing insulation strength (>4kV), thermal distribution, and luminous efficiency.

Design Considerations

- Thermal Management Priority: Design dense thermal vias under LED solder points, connecting to thick copper layers or heat sinks;

- Current Control: Integrate constant current drivers or current-limiting resistors to prevent LED burnout from current fluctuations;

- Protection Design: Add waterproofing for humid environments and overvoltage/surge protection for outdoor use;

- Optical Optimization: Ensure uniform LED placement to avoid shadows, use 3D structures for directional lighting (e.g., fixed-angle marine lights).

Future Trends of LED PCBs

As LEDs advance toward “higher power, intelligence, and integration,” LED PCBs will show three trends:

- Material Upgrades: Higher thermal conductivity composites (e.g., graphene-reinforced aluminum) gain adoption;

- Smart Integration: Integrating sensors and driver chips for adaptive luminous efficiency adjustment;

- Green Manufacturing: Recyclable metal substrates and lead-free processes become mainstream, reducing environmental impact.

FAQ: Your LED PCB Questions Answered

Q1: Why is heat dissipation critical for LED PCBs?

A: LEDs are extremely temperature-sensitive. Poor heat dissipation accelerates light decay and shortens lifespan. Quality LED PCBs control temperatures below 60℃, extending lifespan to over 25,000 hours.

Q2: How to choose the right LED PCB type?

A: FR4 for low power, mid-grade aluminum for medium power, copper/ceramic for high power or extreme environments, and flexible PCB for irregular designs.

Q3: What’s the lifespan of LED PCBs?

A: Quality aluminum LED PCBs last over 3.5 times longer than standard aluminum IMS PCBs, supporting 5-10 years under normal use.

Choose Us for Reliable LED Lighting Cores

- Quick Turn Prototype

- SMT/THT Assembly

- Mixed Assembly

- Lead Free Assembly

- Fast Turnaround PCB Assembly

- Prototype & High Volume

- 100% Electrical Testing

- Impedance control

- Blind,Buried and Plugged Vias

- BGA Assembly

- High-Temp,FR4,Flex,HDI,Rogers,etc

Top Quality Guarantee:

100% electrical testing, AOI, IQC, OQC, and X-ray inspection for defect-free PCBs, which meet RoHS, ISO9001 standards and the standards of IPC Class II. We always react immediately if any issue and provide a quick solution. JC PCBA guarantee the quality, free maintenance and after-sales service for 2 years.

Privacy Protection:

Customer design files are confidential information. We strictly protect all information provided by our customers, ensuring your proprietary information is protected from disclosure, all data is secured and encrypted.

1-on-1 Service :

We taking full responsibility for every customer while offering dedicated 1-on-1 technical team support throughout the pre-sales, in-sales, and after-sales stages. During production, our 1-on- 1 sales will keep you updated of all the progress immediately enable you to master every detail of the production process.

Fast, Efficient, No MOQ:

Generally, our PCB sample take 1-3 days, mass production takes 5-7 days, PCB assembly samples are completed in 10-15 days, and PCB assembly mass production is finished within 15-20 days. Besides, we have one fast sample line for urgent orders.

HOW TO GET A QUOTE: If you want to get a quick quotation for the PCB, please reach us at sales@pcbcustom.com.

Related Posts

Telecom PCBs Manufacturing: Printed Circuit Board in Telecommunication

Smart Home PCB Manufacturing & PCBA Services

Medical PCB Assembly and Manufacturing

LED PCBs: Building the Core of Efficient Lighting

Industrial PCBs Manufacturing & PCBA Services

Consumer Electronics PCBA Manufacturer – JCPCB

Automotive PCBs Manufacturing & PCBA Services

Contact Us

Help you easily achieve your electronic product.

Headquarter Address

SEG Plaza 4406A,No. 1002, Huaqiang North Road,Fuqiang Community, Huaqiang North Street, Futian District. Shenzhen

Factory Address

1st Floor, Building 2, Fenghuang Community, Fuyong Street, Baoan District, Shenzhen, Guangdong, China

Phone

+86-755-85122468

sales@pcbcustom.com

Get Free Quote

Our 1-on-1 sales engineer will reply as soon as possible and quote you within one day!