Quality Assurance

You Trusted Partner in China - JCPCB

We stand behind the quality of our products with a comprehensive warranty.

Quality is as central to JC PCBA as it is to the clients we serve. We leave no detail unexamined, embedding rigorous quality checks into every step of the production and assembly process. At the heart of our quality management efforts is a commitment to building and sustaining the trust of our customers.

We are an Intelligent PCBA factory with advanced technology and equipment. Our advanced PCB technology allows us to provide high precision boards suitable for industrial, military, aerospace, and medical applications. We are continuously investing advanced equipments for fully automated production lines, which enables us to offer our customers high throughput with consistently high quality.

100% electrical testing, AOI, IQC, OQC, and X-ray inspection for defect-free PCBs, which meet RoHS and ISO9001 standards, with a quality control system producing to the standards of IPC Class II. We always react immediately if any issue and provide a quick solution. JC PCBA guarantee the quality, free maintenance and after-sales service for 2 years.

Customer Review

- Product pass rate:>99%

- Timely delivery rate:>98%

- Customer complaint rate:<1%

- Customer satisfaction rate:>99%

Quality Commitment

- File Review Before Production

- Raw Materials Guarantee

- Advanced equipments

- Strict Management

Quality Management of Components

JC Team is committed to providing high quality and reliable semiconductor products. To help reduce the risk of counterfeit products. Also, we can assist customers in their testing and certification by providing corresponding test reports.

To clarify the items and contents of test of purchasing materials, and strictly control the process of unqualified products to ensure product quality.

-

100% Original

-

Anti-counterfeit

-

Speed Delivery

-

ISO9001

-

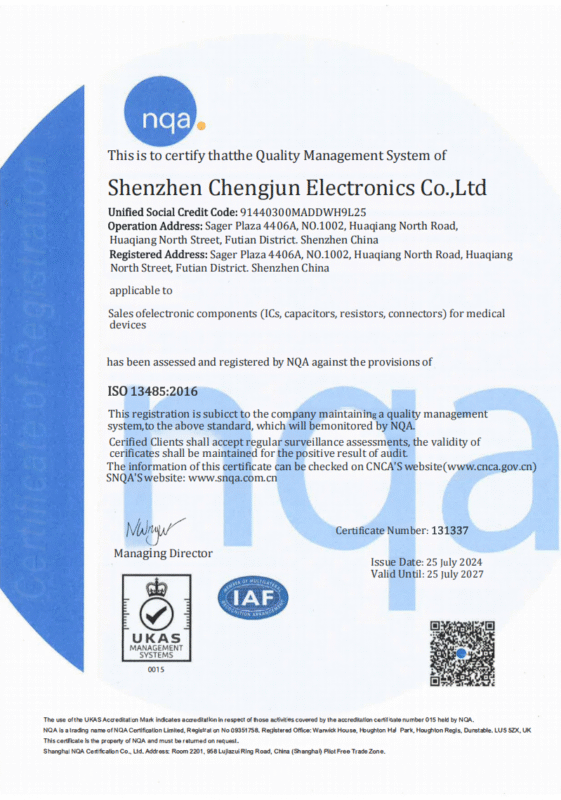

ISO13485

-

IATF16949

Packing Test

Observe whether the outer box packing is intact, whether the packing meets the customer’s requirements (system remarks), and whether the vacuum packing is well preserved (MSL2 level and above); Check whether the braid is disconnected, squeezed and deformed; Check whether there is any supplier changing the packing, and whether the direction of materials and braids meet the requirements;

Label Test

Check whether the model and specification of purchasing materials match those required in the purchase order; Check whether the brand on the original label match that of the system; Check whether the material D/C match the system remarks (Meet requirements within two years by default); Check whether the label anti-counterfeiting meets the requirements of the original manufacturer; Check whether there are marks of label change, whether the stickiness of labels meets the requirements and whether the environmental protection information such as ROHS and PB Free on the label meets the requirements of the original manufacturer and customers.

Our Commitment to Quality of PCB

Committing to rigorous quality assurance measures to deliver products that exceed industry standards.

PCB Raw Material

Our PCB boards use genuine Grade-A materials, such as Jian Tao (KB) and Nanya (NY). Good dimensional stability after heating. Curvature of the board ≤0.75%, Not easy to deformation and plate warping; The copper coating on the hole wall has better adhesive force; no layered or drape in copper. Drilling Roughness ≤25.4UM.

Technology Standard

Standard copper PTH technic makes copper in vias reach 20-22UM. Even better than IPC class 2 requirement (via copper thickness 18-20UM). lesser risk of copper shedding in faults and holes when under high current or high temperature.

Solder Mask

High-quality solder mask inks from brands like Ronda are applied using a photosensitive process. Glossy ink, strong color. Solder resistance thickness up to standard 8-30UM. Help to achieve better filling via with resin and better adhesive force solder mask on your PCB.

Plating&Surface Treatment

Premium electroplating and surface treatment chemicals are employed to achieve a 100% yield rate. Lesser soldering problem, BGA solder risk, make sure copper in via, surface treatment has strictly control within IPC standard. The pollution and oxidation of the board surface, black nickel, abnormal nickel thickness, SCUM (shadow) and other problems are strictly controlled during the operation process.

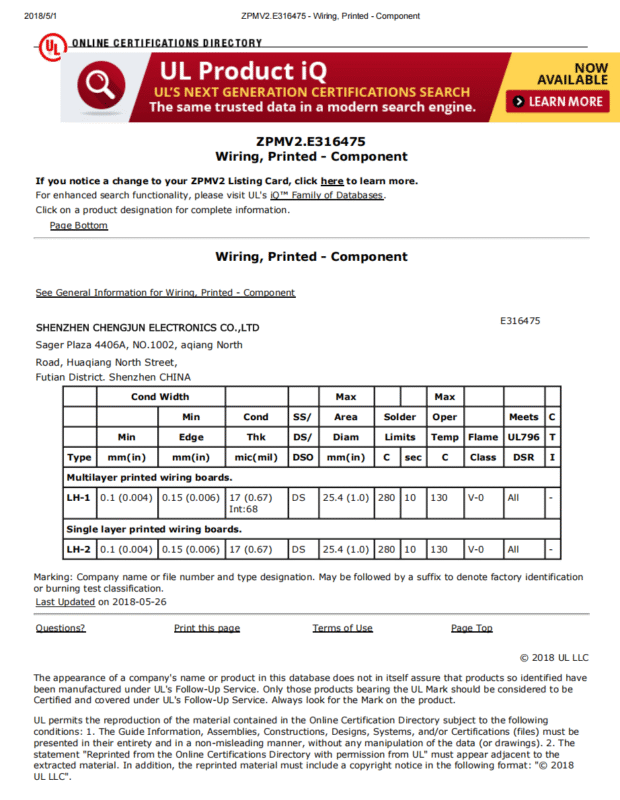

Our Certifications And Honor

JCPCB has lS09000,IS014001,ISO13458,UL,RoHS and IATF16949 certifications, etc. In addition, we help with compliance testing for global certifications like CE/FCC/UL/ROHS. This streamlines your path to market access. We have professional quality assurance team and quality control system to ensure the electronic products with quality stability. JC teams offer high-quality services and make sure you get projects according to the required details.

Working with us will be the best experience for you.

IPC-A-610D-G

The standard is recognized worldwide and supports the electronic manufacturing process.

The IPC (Association Connecting Electronic Industries) previously known as the Institute for Printed Circuits created the standards to ensure that the products built by electronics companies are manufactured to the highest standards.

The acceptance criteria for visual inspection of electronic component manufacturing and electronic assembly quality of the company’s products shall be established by the IPC Product Assurance Committee.

RoHS

Our company complies with the requirements of the RoHS 2.0 directive, and the products purchased by customers conform to the RoHS – standard list of substances prohibited by the RoHS Directive. The specific prohibited substances include lead (Pb), mercury (Hg), cadmium (Cd), hexavalent chromium (Cr⁶⁺), polybrominated biphenyls (PBBs), polybrominated diphenyl ethers (PBDEs), bis (2 – ethylhexyl) phthalate (DEHP), benzyl butyl phthalate (BBP), dibutyl phthalate (DBP), and diisobutyl phthalate (DIBP). The maximum concentration limits for these substances are generally 1000 ppm for lead, mercury, hexavalent chromium, PBBs, PBDEs, DEHP, BBP, DBP, and DIBP, and 100 ppm for cadmium.

ESD Protection

ESD (Electrostatic Discharge) is a common potential threat in the electronics manufacturing industry, which may cause damage to electronic components, degradation of product performance, or failure. ESD protection refers to the use of systematic measures to control the generation, accumulation, and release of static electricity, protecting electronic components, assemblies, and finished products during production, storage, transportation, and use.

1.Prevent electrostatically sensitive components (such as ICs, chips, precision circuits, etc.) from being damaged by electrostatic discharge;

- .Ensure stable product quality during production, reducing scrap and rework rates caused by ESD;

- Comply with industry standards (e.g., ANSI/ESD S20.20, IEC 61340) to guarantee product reliability and market access.

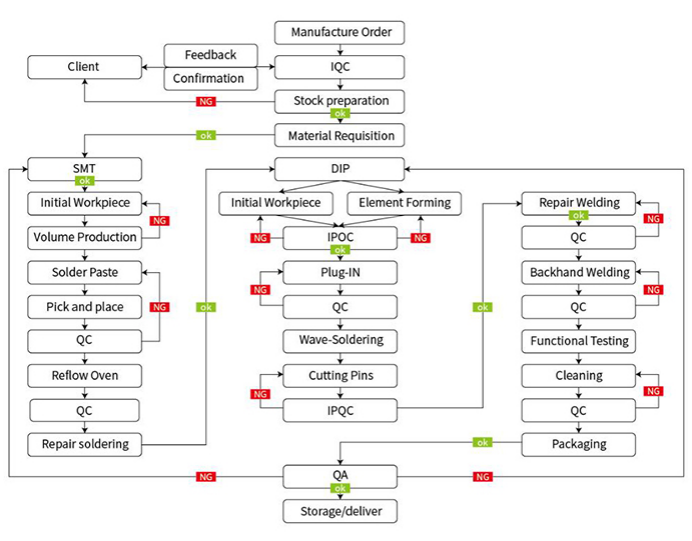

Quality Control Process

The entire project process strictly implements the quality management system, and ensures every link through standardized, data-based and written methods.

PCBA Inspection

Our range of test capabilities include: Automated Test Equipment、Flying probe、 AOI (Automated Optical Inspection)、X-Ray、Burn-in(temperature soak)、 Mechanical fixturing、ICT(in-circuit test)、Solder Paste Inspection、MDA (manufacturing defect analysis)、In-circuit functional test、Automated test、software development、Manual、Electrical safety test、RF test(radio-frequency)、Cable/Harness Test.

- Key Processes: incoming Material inspection - Printing - SPl inspection - SMT Placement - First Article Inspection Reflow Soldering - AOl - insertion - Wave Soldering - Testing - Frequency Adjustment - Aging - Quality Inspection;

- Inspection Processes: Incoming Material inspection - SPl lnspection - First Article Inspection - AOl- Microscope Inspection - Functional Test Inspection -Quality Appearance inspection;

- Laboratory - Aging Test - Vibration Test Equipment - Drop Test Equipment - Salt Spray Test Equipment - Constant Temperature and Humidity Chamber - Dielectric/Earth Bond Test Equipment

- Key Equipment: Printer - SPl - SMT Machine - Reflow Soldering - AOl Equipment - Wave Soldering

Production & Quality control management

Standardized operation process specification, process inspection to ensure that production and quality anomalies can be found and corrected in time, OQC further ensures product quality.

IQC

– Verifying that all PCBs, components, stencils, and fixtures align with specified requirements—ensuring quality issues are prevented from the outset.

– PCB: Thickness, vias, pads, silkscreen, wrapping degree, circuits solder mask, ect; Components: Part-number,quantity, value, RoHS,appearances, solder pins, temperature resistance, ect.

– Components: Part-number, quantity, value, RoHS, appearances, solder pins, temperature resistance, ect

Storage

– Sensitive Components Storage: Sensitive chips are stored in humidity-controlled cabinets maintaining 5% relative humidity to preserve their integrity.

– RoHS Compliance Labeling: Post IQC inspection, external packaging of components is clearly marked with “RoHS” or “Non-RoHS” to ensure compliance transparency.

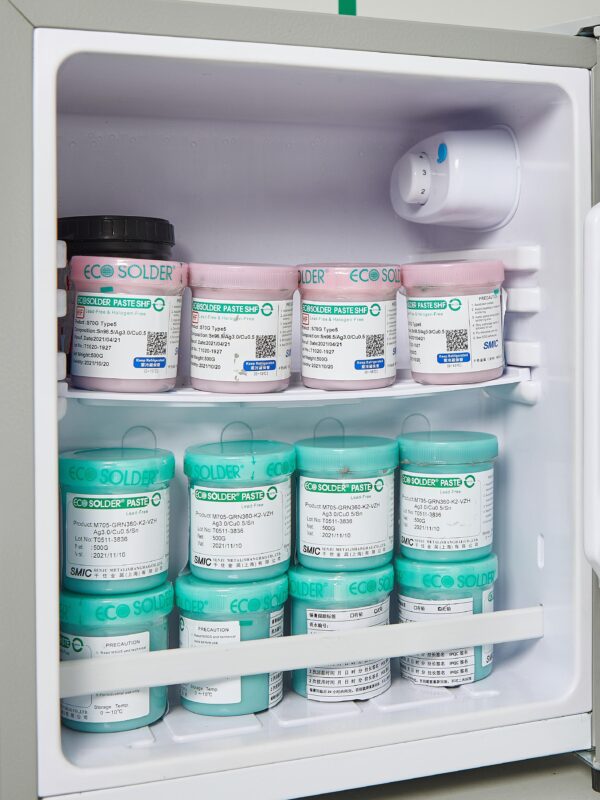

– Solder Paste Management: Solder paste is hermetically sealed and stored in refrigerators set to 2-10℃, with each unit labeled prominently with its expiration date.

Solder paste

– We source solder paste from leading brands such as ECO, Alpha, and Vital to ensure consistent material quality.

– Solder paste is processed using automated mixing equipment, which stirs clockwise for 2–5 minutes until it reaches a filamentous consistency—after which it is immediately deployed in production.

– We exclusively use laser stencils from reputable manufacturers, with special attention to high-precision solder pads like those for QFN, BGA, and similar components.

– Our SPI (Solder Paste Inspection) system monitors solder paste thickness, area, and volume distribution through non-contact laser 3D scanning with intensive sampling. This allows our team to identify and address paste-related issues at this stage, preventing soldering defects before PCBA enters the reflow oven.

– The maximum application range is 80UM thick screen plate printing 20um diameter circle, good polymerization can greatly reduce the double ball phenomenon, ensure lead-free reflux, more fine solder joint fusion, good weld ability, help greatly improve the production yield.

SMT soldering

– Our reflow ovens feature 12 temperature zones, allowing extended time for solder paste melting and solidification. This ensures smoother temperature ramps and cool-downs, effectively minimizing soldering defects caused by thermal shock.

– Each production line is equipped with AOI (Automated Optical Inspection) systems at the final stage. These systems automatically scan PCBs via cameras, capture images, and compare them against qualified templates in the database—enabling rapid detection of soldering anomalies and significantly boosting QC efficiency.

– We utilize X-ray inspection equipment to assess soldering quality for BGA chips, ensuring reliable joints in hard-to-visualize areas.

– Full first-article inspection is mandatory before mass production commences. For instance, design data, component designators, and values are uploaded to a verification database to confirm that the first article fully aligns with the specifications in the client’s design files.

Quality Management Team - JC Team

All employees are encouraged to take responsibility for the quality of their own workmanship and to work with their colleagues towards the goal of “zero defects”, a philosophy emphasised throughout the company, not just limited to those directly involved with manufacturing output. We have a dedicated on site quality manager who continuously reviews our practices and procedures to ensure that we maintain a high standard of product quality and we constantly look to improve our systems towards the goal of “zero defects”. Our Quality Manager is on hand to deal with any customer queries on a one to one basis.

Equipped with advanced circuit board production equipment, our company employs experienced professionals for management and operates a complete, scientific quality management system

Professional customer service personnel

- BOM engineers

- Process engineers

- PMC

- PCB engineers

- Purchasing personnel

- IQC

- Production supervisors

- Production personnel

- Process control engineers

- OQC

- logistics personnel

Package Method

PCBA boards are delicate and prone to damage, so we prioritize robust packaging protocols before shipping. Each unit is carefully wrapped using bubble wrap, pearl cotton, anti-static bags, and vacuum-sealed packaging—effectively safeguarding against static interference and physical impact during transit.

-

INNER:

PCB: Vacuum Packing

PCBA: ESD Packing

-

OUTER:

Standard export carton

Customized Package

The customized outer box has good breaking strength and side pressure strength, and strong shock resistance and compression performance, The electrostatic shielding baa is dust proof, moisture -proof and electrostatic proof, which prevents PCBA components from being damaged to a certain extent. Adding anti-static bubble baa can effectively prevent collision parts, Protective pearl-cotton reinforced packaging anti-collision and anti-extrusion. A variety of safeguards ensure that the rate of breakage in the logistics process is kept to a minimum.

Our PCBA Solutions Across Industries

safety protection, electrical appliances, digital home appliances, and more.

Our Testimonials

PCB&Assembly

Everything is good, PCBs work good by now, thank you(Gracias)! To JC Teams.

PCBA programming,conformal coating,testing.

The boards are prefect, I am really happy to receive my boards, the components are really good!

3D Printing&Injection Molding

I am very pleased to work with you(Sulin)! It feels like you are a professional!

PCB Manufacturing

Uploaded my Gerber files, got a quote in hours, and parts arrived sooner than quoted. Nice.”

PCBA Prototyping& Batch production

I am happy to find you(Jason)!No minimum order hassle, and the soldering looks good, cleanly well.

PCBA and components and modules.

We tested all, PCBs works well, thank you! Michael.

PCB Assembly&Testing

Consistently excellent. Quick responses from Joy.

Contact Us

Help you easily achieve your electronic product.

Headquarter Address

SEG Plaza 4406A,No. 1002, Huaqiang North Road,Fuqiang Community, Huaqiang North Street, Futian District. Shenzhen

Factory Address

1st Floor, Building 2, Fenghuang Community, Fuyong Street, Baoan District, Shenzhen, Guangdong, China

Phone

+86-755-85122468

sales@pcbcustom.com

Get Free Quote

Our 1-on-1 sales engineer will reply as soon as possible and quote you within one day!