Industrial PCBs Manufacturing & PCBA Services

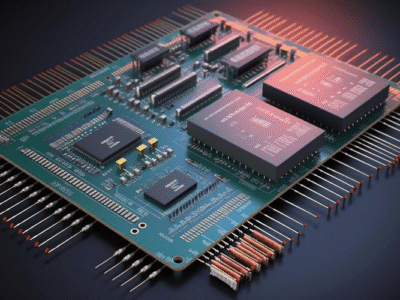

Industrial PCBs are specialized circuit boards engineered to thrive in harsh operating conditions—think extreme temperatures, heavy vibrations, high humidity, and corrosive environments. Unlike commercial PCBs designed for short lifespans (1-3 years) in stable settings like offices or homes, industrial PCBs are built for longevity, typically lasting 5-15+ years. They adhere to strict standards like IPC Class 3, ensuring reliability in critical applications where failure could lead to downtime, safety risks, or financial losses.

What is an Industrial PCB?

Industrial PCBs are engineered for extreme operating environments, delivering consistent performance under:

- Temperature extremes (-40°C to 150°C)

- High vibration (up to 5Grms)

- Humidity/IP67-rated contamination

- Electromagnetic interference

Rigorous testing and inspection for PCB

To ensure that your PCBs are functioning optimally, we can provide comprehensive testing and inspection throughout the design and manufacturing process.

Before manufacturing:

DFM & DFA checks

BOM checks

Special stack-up help / NPI review

Component engineering assistance and procurement

After manufacturing:

Functional inspections

Thermal cycling tests (TCT)

Thermal shock tests (TST)

Temperature-humidity bias tests (THB)

AOI report or visual inspection report

Flying probe or in-circuit testing report

Manufacturing Industrial PCBs: Key Steps & Considerations

Critical Steps:

- Design & DFM Review: Engineers use Altium to create Gerber files, followed by Design for Manufacturability checks to verify trace widths, hole sizes, and material compatibility.

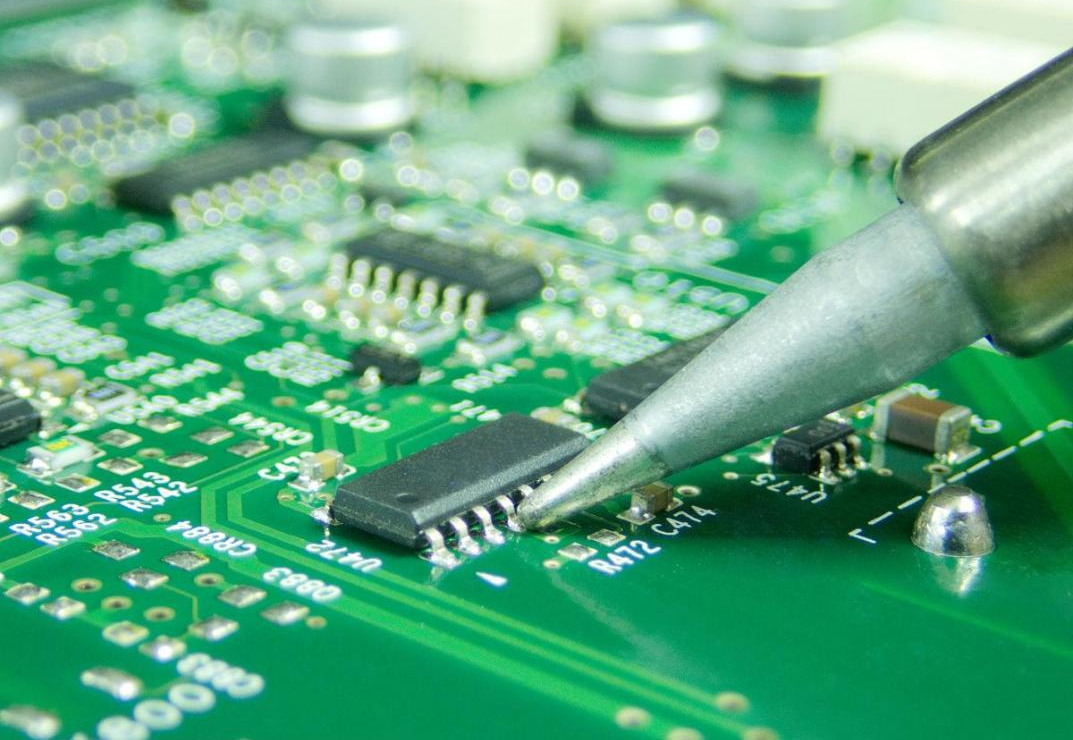

- Cleaning & Drilling: Panels are cleaned to remove contaminants, then drilled for component placement and layer connections (using CNC machines for accuracy).

- Electroplating & Etching: Copper is deposited in holes to connect layers; unwanted copper is removed via alkaline etching.

- Inspection & Testing: Automated Optical Inspection (AOI) and X-ray detect flaws. Electrical tests (ICT, flying probe) ensure no shorts or opens.

- Coating & Finishing: Solder masks protect copper, while conformal coatings (epoxy, acrylic) add moisture/corrosion resistance.

Industrial PCB Comparison Matrix

| Type | Applications | Key Advantages | Standard Materials |

| Metal Core PCBs | High-power LEDs/Power modules | Thermal conductivity: 8-12W/mK | Aluminum/Copper substrates |

| High-Tg FR4 | Industrial controllers | Tg ≥180°C | IT-180A/Isola 370HR |

| Polyimide Flex | Robotic joint wiring | >1M bend cycles | Kapton®/UPILEX® |

| Ceramic Substrates | Automotive electronics | CTE-matched to ICs | Al₂O₃/AlN |

| Heavy Copper PCBs | Power converters | 400μm copper thickness | FR4 + HVLP foil |

Why Choose JCPCBA for Your industrial PCB Assembly Needs?

- Quick Turn Prototype

- SMT/THT Assembly

- Mixed Assembly

- Lead Free Assembly

- Fast Turnaround PCB Assembly

- Prototype & High Volume

- 100% Electrical Testing

- Impedance control

- Blind,Buried and Plugged Vias

- BGA Assembly

- High-Temp,FR4,Flex,HDI,Rogers,etc

Top Quality Guarantee:

100% electrical testing, AOI, IQC, OQC, and X-ray inspection for defect-free PCBs, which meet RoHS, ISO9001 standards and the standards of IPC Class II. We always react immediately if any issue and provide a quick solution. JC PCBA guarantee the quality, free maintenance and after-sales service for 2 years.

Privacy Protection:

Customer design files are confidential information. We strictly protect all information provided by our customers, ensuring your proprietary information is protected from disclosure, all data is secured and encrypted.

1-on-1 Service :

We taking full responsibility for every customer while offering dedicated 1-on-1 technical team support throughout the pre-sales, in-sales, and after-sales stages. During production, our 1-on- 1 sales will keep you updated of all the progress immediately enable you to master every detail of the production process.

Fast, Efficient, No MOQ:

Generally, our PCB sample take 1-3 days, mass production takes 5-7 days, PCB assembly samples are completed in 10-15 days, and PCB assembly mass production is finished within 15-20 days. Besides, we have one fast sample line for urgent orders.

HOW TO GET A QUOTE: If you want to get a quick quotation for the PCB, please reach us at sales@pcbcustom.com.

FAQ

Q: How is an industrial PCB different from a commercial one?

A: Industrial PCBs handle wider temperatures (-65°C to 150°C), vibrations (10-500Hz at 10G+), and have longer lifespans (5-15+ years). They also meet stricter standards like IPC Class 3.

Q: What materials are best for high-heat applications?

A: Ceramic substrates (Al2O3) or high Tg FR-4 (Tg >170°C) work best for sustained high temperatures.

Q: Do industrial PCBs require special testing?

A: Yes—tests include burn-in (long-term operation), thermal cycling, vibration/shock trials, and corrosion resistance checks.

Conclusion

Industrial PCBs are more than just circuit boards—they’re the foundation of reliable, long-lasting industrial systems. Whether you need a board for a factory floor or a deep-sea drilling tool, partnering with experts ensures your electronics survive and perform, no matter the conditions. Contact us at sales@pcbcustom.com today to start your custom industrial PCB project!

Related Posts

Telecom PCBs Manufacturing: Printed Circuit Board in Telecommunication

Smart Home PCB Manufacturing & PCBA Services

Medical PCB Assembly and Manufacturing

LED PCBs: Building the Core of Efficient Lighting

Industrial PCBs Manufacturing & PCBA Services

Consumer Electronics PCBA Manufacturer – JCPCB

Automotive PCBs Manufacturing & PCBA Services

Contact Us

Help you easily achieve your electronic product.

Headquarter Address

SEG Plaza 4406A,No. 1002, Huaqiang North Road,Fuqiang Community, Huaqiang North Street, Futian District. Shenzhen

Factory Address

1st Floor, Building 2, Fenghuang Community, Fuyong Street, Baoan District, Shenzhen, Guangdong, China

Phone

+86-755-85122468

sales@pcbcustom.com

Get Free Quote

Our 1-on-1 sales engineer will reply as soon as possible and quote you within one day!