Consumer Electronics PCBA Manufacturer – CJPCB

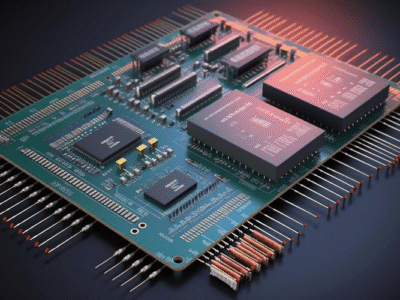

PCB is the “backbone” and “nervous system” of consumer electronic products. PCs and laptops, smartphones, wearables, smart home devices, consumer electronics are at the center of our daily personal and professional lives. At the core of all this is the printed circuit board (PCB), the most effective method of interconnecting electronic components and powering other devices. PCBs for consumer electronics have come a long way since then, with newer materials and designs being utilized to keep pace with the needs of smaller and more capable devices.

What is a Consumer Electronics PCB?

A Consumer Electronics PCB is a flat board made of non-conductive materials (usually fiberglass-reinforced epoxy resin like FR-4) with conductive copper traces etched onto its surface. It serves as the physical platform that connects and powers electronic components such as chips, resistors, and capacitors in consumer devices. Unlike industrial or automotive PCBs, consumer electronics PCBs prioritize compactness, lightweight design, and cost-effectiveness while meeting strict performance standards. According to IPC (Association Connecting Electronics Industries) standards, these PCBs must ensure reliable signal transmission and durability in everyday use.

Applications of Consumer Electronics PCB

- Telephones

- Television Sets

- Digital Cameras

- Smartphone

- Tablets

- Computers

- Laptops

- Camcorders

- DVD players

- Stereo Players

- Video Gaming Consolers

Key Considerations in Consumer Electronics PCB Production

- Material Selection: FR-4 is the standard choice for most devices, while high-frequency materials like Rogers are used for 5G-enabled gadgets to minimize signal loss.

- Precision Control: Line widths and spacing as small as 0.1mm are required for high-density devices, demanding advanced etching technologies.

- Thermal Management: Heat dissipation layers (e.g., aluminum cores) prevent overheating in power-intensive devices like gaming laptops.

- Compliance: Adherence to RoHS (Restriction of Hazardous Substances) and UL (Underwriters Laboratories) certifications ensures safety and environmental friendliness.

Comparison of Different Consumer Electronics PCB Types

| PCB Type | Structure | Key Features | Typical Applications |

| Single-sided PCB | Copper traces on one side | Low cost, simple design | Remote controls, basic calculators |

| Double-sided PCB | Copper traces on both sides | Better component density, through-hole vias | Microwaves, small audio devices |

| Multi-layer PCB | 3+ layers with inner traces | High density, signal integrity | Smartphones, laptops, gaming consoles |

| Rigid-Flex PCB | Combination of rigid and flexible layers | Space-saving, durable | Smartwatches, medical devices |

Consumer Electronics PCB Cases

- Smart Home Control Panel: A 4-layer PCB with integrated Wi-Fi and Bluetooth modules, designed to handle multiple sensor inputs (temperature, motion) in a compact 10x15cm form factor.

- Fitness Tracker PCB: A rigid-flex 2-layer PCB weighing under 5g, featuring low-power components and waterproof coating to withstand sweat and moisture.

Design Tips for Consumer Electronics PCB

- Layout Optimization: Shorten signal paths to reduce interference, especially in high-speed devices like smartphones.

- EMC Compliance: Incorporate grounding planes and filter components to minimize electromagnetic interference (EMI).

- Component Placement: Group related components (e.g., power management ICs) to simplify wiring and improve efficiency.

- Future-Proofing: Leave extra PCB space and interface ports for potential upgrades (e.g., USB-C instead of micro-USB).

FAQ About Consumer Electronics PCB

Q: Can Consumer Electronics PCBs be recycled?

A: Yes, copper traces and precious metals can be recycled, aligning with eco-friendly practices.

Q: What’s the difference between consumer and industrial PCBs?

A: Consumer PCBs focus on cost and size, while industrial PCBs prioritize ruggedness and high-temperature resistance.

Q: What’s the difference between flexible PCBs and rigid PCBs?

A: Flexible PCBs use polyimide substrates and can bend/fold (e.g., smartwatch straps), while rigid PCBs use FR-4 substrates with fixed shapes (e.g., laptop motherboards). Flexible PCBs cost about 30% more than rigid PCBs of similar specifications.

Why Choose CJPCBA for Your Consumer Electronics PCB Assembly Needs?

Top Quality Guarantee:

100% electrical testing, AOI, IQC, OQC, and X-ray inspection for defect-free PCBs, which meet RoHS, ISO9001 standards and the standards of IPC Class II. We always react immediately if any issue and provide a quick solution. CJ PCBA guarantee the quality, free maintenance and after-sales service for 2 years.

Privacy Protection:

Customer design files are confidential information. We strictly protect all information provided by our customers, ensuring your proprietary information is protected from disclosure, all data is secured and encrypted.

1-on-1 Service :

We taking full responsibility for every customer while offering dedicated 1-on-1 technical team support throughout the pre-sales, in-sales, and after-sales stages. During production, our 1-on- 1 sales will keep you updated of all the progress immediately enable you to master every detail of the production process.

Fast, Efficient, No MOQ:

Generally, our PCB sample take 1-3 days, mass production takes 5-7 days, PCB assembly samples are completed in 10-15 days, and PCB assembly mass production is finished within 15-20 days. Besides, we have one fast sample line for urgent orders.

HOW TO GET A QUOTE: If you want to get a quick quotation for the PCB, please reach us at sales@pcbcustom.com.

Conclusion

Consumer Electronics PCBs are the foundation of modern gadgets, and choosing the right manufacturing partner is crucial for product success. Whether you’re developing a new smartphone or a smart home device, we’re here to turn your design into a reliable, high-quality PCB solution. Contact us at sales@pcbcustom.com today to get started!

Related Posts

Telecom PCBs Manufacturing: Printed Circuit Board in Telecommunication

Smart Home PCB Manufacturing & PCBA Services

Medical PCB Assembly and Manufacturing

LED PCBs: Building the Core of Efficient Lighting

Industrial PCBs Manufacturing & PCBA Services

Consumer Electronics PCBA Manufacturer – CJPCB

Automotive PCBs Manufacturing & PCBA Services

Contact Us

Help you easily achieve your electronic product.

Headquarter Address

SEG Plaza 4406A,No. 1002, Huaqiang North Road,Fuqiang Community, Huaqiang North Street, Futian District. Shenzhen

Factory Address

1st Floor, Building H, Tangxi No.2 Industrial Zone, Xijing Road, Gushu, Bao’an District, Shenzhen

Phone

+86-755-85122468

sales@pcbcustom.com

Get Free Quote

Our 1-on-1 sales engineer will reply as soon as possible and quote you within one day!